Ensuring the highest performance

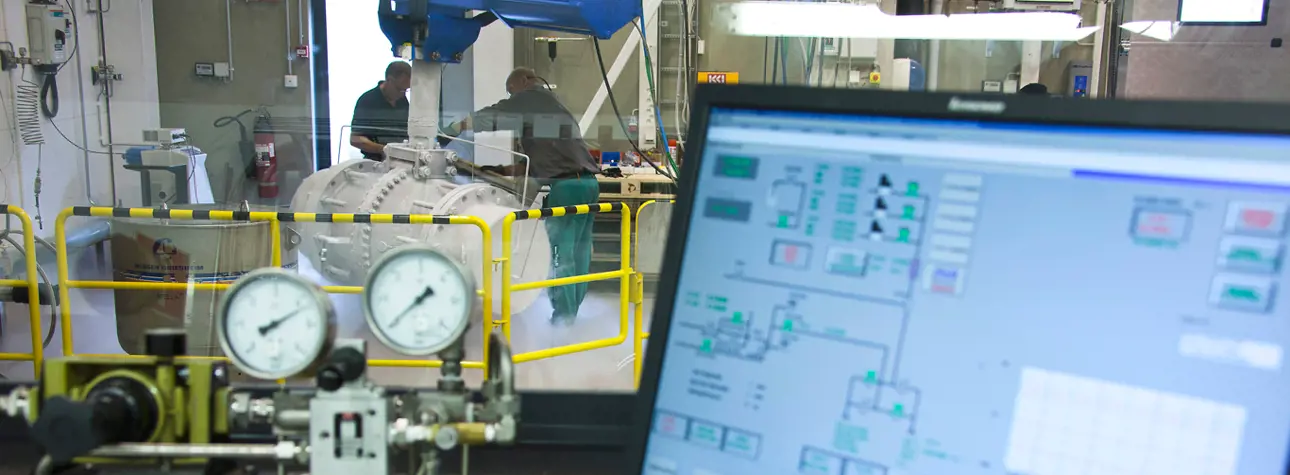

Our global footprint can be seen in our valve technology centers, each combining R&D and a technology laboratory. Our five valve technology centers are located in Finland, USA, Germany, China and Korea. The main functions of these facilities are to verify and validate products and their performance.

Many requirements for our products come from international standards and from customer specifications. The standards and specifications usually require demanding tests and a deep understanding of related issues. The primary focus of these requirements are safety, the environment and operational performance. The design and set-up for all this testing requires the development of unique and specialized equipment, as well as deep knowledge of process automation and data acquisition.

Flow testing

One of the fundamental requirements in valve technology is flow testing. Valve flow coefficients are determined from flow measurements. The correct flow coefficients are essential to be able to select the correct valves for our customer’s process applications. Accurate flow coefficients yield better process efficiency, longer life expectancy, as well as lower investment and usage costs for our customers.

The main control valve sizing coefficients measured in our flow laboratories are the valve flow characteristics, flow coefficient (Cv), valve pressure recovery factor (FL), differential pressure ratio of incipient cavitation noise (xFz), and pressure differential ratio factor at choked flow (xT). Also valve hydrodynamic and aerodynamic noise levels are measured for determining noise coefficients.

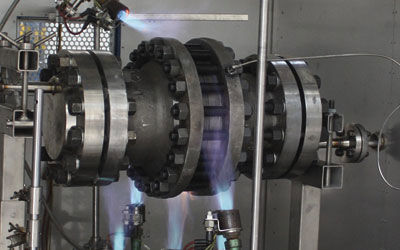

Fire testing

Fire tests are done according to industry or customer standards. A fire test simulates a fire in a plant or a factory and verifies that the valve stays tight enough to prevent internal or external leakage from expanding the size of the fire. The basic test is to expose the valve to high temperature flames for 30 minutes and then rapidly cool with cold water. Cooling with cold water simulates attempts to extinguish a fire and exposes the valve to severe thermal shock.

Fugitive emissions testing

Fugitive emissions are leaks and spills from industrial processes. Fugitive emissions from valves are generally gaseous substances, which can be hazardous or lethal to people, or are damaging to the environment, such as severe greenhouse gases. Fugitive emissions from industrial processes are regulated and monitored closely by governments all around the world, and demands for tighter limits continue to be applied. High-quality testing plays a vital role in developing new and better sealing technologies, minimizing fugitive emissions from our valves. Laboratories have state-of-the-art testing equipment, and extremely experienced personnel.

Internationally recognized testing standards are used to verify and classify the fugitive emissions performance of our valves.

Testing for fugitive emissions is difficult and demanding. A valve is tested by pressurizing it, normally with helium or methane gas, up to its maximum design pressure, which can be as high as 250 bars. Any leaking test gas is then detected from outside the valve with a highly sensitive mass spectrometer, gathering every atom of gas. The test temperature cycles between the minimum to maximum rating and can vary from -196 to over 400 degrees Celsius. During a fugitive emissions test the valve is operated tens or even hundreds of thousands of times.

Endurance testing

Endurance tests are performed to learn and understand the effects of repetitive cycling and cycle speeds on valve tightness, operating torque, and to monitor the wear behavior of parts. Actuators are tested separately and with valves to demonstrate the total package performance. The number of cycles in an endurance test can exceed 5 million. Endurance tests are regularly performed in all Neles valve testing facilities under various process and environmental conditions.

Pressure testing

One aspect of pressure testing is to ensure that pressure-containing products are safe and are more than capable of withstanding their defined ratings. In addition, tightness tests are done to verify the valve sealing performance under different pressures, temperatures, and process media.

Actuator testing

Our Valves are designed to be used in most, if not all, environments found on this planet. That means the actuator operating the valve also needs to endure and work flawlessly in these potentially harsh conditions. Actuators are used in the hottest locations on earth, as well the coldest arctic conditions, where temperatures reach below -50 degrees Celsius. Under such severe extremes, actuators work for many millions of cycles. To be able to provide actuators for such conditions, the performance must first be verified in valve technology laboratories.

The performance verification of valve actuators includes endurance testing, speed testing, control accuracy, output torque, environment testing, as well as ingress protection and vibration. Endurance tests are conducted using specialized test benches with variable resistance, enabling the actuator to be operated under load for millions of cycles. Actuator output torques are measured with high-precision torque transducers to ensure that they consistently produce the expected output.

Environmental testing

Since our valves are used in such a wide variety of environments and process conditions, we must be able to duplicate these demanding conditions in order to test and verify product performance. Our laboratories have environmental test chambers and rooms where the temperature and humidity can be selected and controlled. Our standard equipment simulates temperatures as low as -75˚C to over +800˚C. Salt spray chambers are used for accelerated corrosion testing to verify the performance of paints and other coatings. Vibration tables are used to simulate and prove the capability of our products to withstand such severe process conditions. Our vibration tables are also used to verify valve control performance when exposed to a wide range of frequencies.

Materials and coatings

Material testing capabilities include metallographic testing for chemical composition and heat treatment, tribology (wear) testing, and corrosion testing. Also extensive and complex analysis of polymers, such as PTFE, is performed.

Metallographic testing is used to verify the quality of materials and coatings from our suppliers. The microstructure of metal is viewed under a high power microscope to evaluate and verify effective heat treatment, and morphology of coatings are also checked. Our laboratories are also equipped to investigate new materials and coatings in conjunction with technology projects. Metallographic testing also plays an important part in failure analysis of broken components. Replica testing (nondestructive metallographic testing) is done without destroying the test parts, which is very useful when the test parts are large and expensive. Portable metal alloy analyzers are used for verification that materials are chemically in accordance with the specification.

Tribology testing evaluates materials and coatings used for valve trim, seats, and bearings. Coated surfaces of two separate samples are pressed together and cycled under a specified force for a defined number of cycles, depending upon how and where the coatings will be used. Test specimens are evaluated and measured for changes in surface roughness after the test. Deep grooves in the mated surfaces indicate that galling has occurred and is not acceptable. Our computerized test instrument automatically calculates the coefficient of friction from the test results. Tribology testing can be done in a range of test temperatures. After testing new coating materials, the best candidates are then tested in valves for tightness and endurance.

Summary

With accurate and reliable performance verification of valve products we are able to give our customers first-hand information about the actual performance level, quality and safety of our products and technologies. This way, our customers can depend on safe valve products while maximizing the productivity of their operations.

Text originally published in 2016, and slightly updated in April 2022, due to the company name change to Valmet.

TEXT: Juha Perttilä and Kari Vierimaa

Published in Results flow control customer magazine 2/2016.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeRead more about valve testing