Pulp washing system fundamentals and design (webinar)

Nov 30, 2021

Many pulp mills are working to adapt to the loss of technical knowledge and experience in the last few years caused by retirements and general attrition of operators. As a result, critical process knowledge doesn’t get passed on to the new operators or there may be a training deficiency surrounding the basics of the process.

In order to operate the pulp washing system efficiently, it is necessary for fiberline operators and superintendents to understand the fundamentals of the washing system. In response to many mill requests, Valmet presents a free webinar on Wednesday, December 8th providing a basic overview of the fiberline pulp washing process.

Click HERE to watch the webinar that was presented by Tom Morrow and Bruno Pannese, Senior Pulp System Engineers.

Learning objectives

- Explore pulp washing system fundamentals and design

- Review washing terminologies

- Understand pulp washing operating parameters

- Review commonly installed washing devices

Here's an excerpt from the webinar...

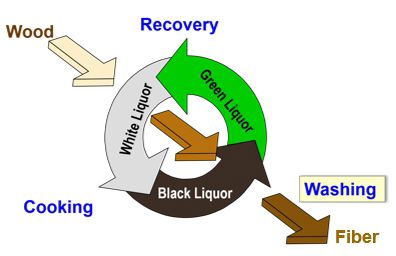

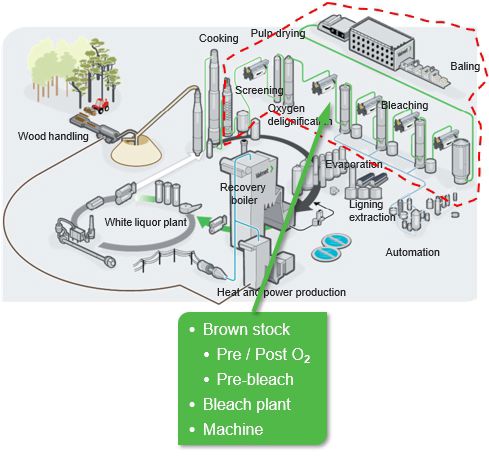

The illustrations show a simplified interpretation of the brown stock washing system and liquor cycle with the balance of the mill.

Cooked / brown stock pulp from the digester is composed of chemically separated suspended wood fibers and black liquor containing the spent cooking chemicals (inorganics), the dissolved wood products (organics/lignin) and water.

The brown stock washing system separates and concentrates the dissolved solids in the black liquor from the suspended fibers and delivers washed pulp, either to the bleach plant in a bleach mill or to the machine in a brown mill. Black liquor from washing is processed in the recovery cycle, first in the evaporators to further concentrate the liquor and then in the recovery boiler to produce energy. Green liquor after the recovery boiler is then regenerated as white liquor for re-use in cooking.

Pulp and liquor character from the digester directly affect the operation and efficiency of the brown stock washing system. Similarly, the effectiveness of the brown stock washing system directly impacts the operation of the paper machine (in a brown mill) or the bleach plant and subsequent paper machine in a bleached pulp mill. In addition, as the liquors washed from the pulp are recovered in the overall process, the brown stock washing system also directly affects the recovery area.

For more information on pulp washing, watch the webinar and contact your Valmet representative.