Breaking through the textile industry

Apr 24, 2024

Renewcell’s Circulose dissolving pulp uses cellulose from discarded textiles that is then spun into soft and breathable new textile materials like viscose and lyocell. Renewcell and Valmet have worked closely on this groundbreaking innovation from the first pilot trials to the first-of-a-kind industrial-scale production line.

Swedish textile company Renewcell has invented a groundbreaking process for recycling and reusing textile waste. The resulting product is a dissolving pulp called Circulose that is made from 100 percent textile waste. Textile producers and fashion brands such as Levi’s, Calvin Klein, H&M, Tommy Hilfiger and many others are now using Circulose to replace raw materials with a high environmental impact like fossil oil and cotton in their textiles. Henrik Dahlbom, the Project Director at Renewcell, explains some of the key benefits of Circulose.

“The textile industry has a significant impact on the environment, and Renewcell is aiming to improve the environmental footprint of textiles. Cotton, for example, demands large quantities of water to grow and process, and it also uses pesticides and fertilizers that pollute the environment. As our process depends only on the recycled garments we shred, we can sell a recyclable product that consumes much less water and chemicals over its many lifecycles.”

Henrik Dahlbom, Project Director at Renewcell, demonstrates the finished cotton sheets.

Professors with a recycling idea

The Renewcell company journey started at Sweden’s Royal Institute of Technology in Stockholm, where a couple of professors were working on recycling cotton from textiles. In the lab, they succeeded in making a pulp from recycled cotton garments that responded well to bleaching for brightening. Thereafter, in 2017, they built a pilot plant in Kristinehamn, Sweden, to scale up the output and make samples for the first customer trials. In parallel, they also conducted design testing for the bleaching process at Valmet’s Fiber Technology Center in Sundsvall.

In 2019, larger-scale samples were sent to key customers, and they received a positive response. So the team decided in 2020 to build the first industrial-scale production line at Ortviken near Sundsvall, and the first saleable Circulose product was shipped in October 2022, with high demand for the material.

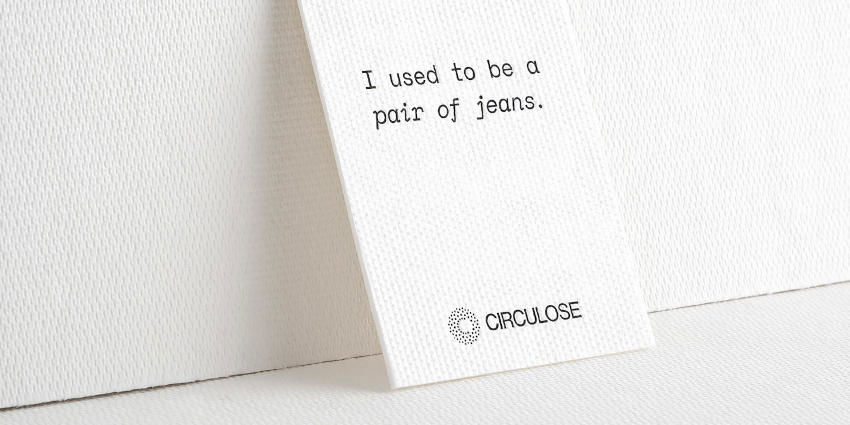

The products are delivered to fiber-producing customers in cotton sheets.

Valmet equipment and expertise

When selecting Valmet as the equipment supplier, Renewcell clearly wanted a partner that complemented its own experts’ process insight with deep knowledge of equipment and best practices. Among the specific capabilities they sought were world-class technology and long experience of supplying equipment to the fiber processing industry, in combination with an animated curiosity about textile recycling and the new dissolving pulp’s special behavior.

There was a shared dedication to making this succeed.

Renewcell’s Dahlbom says that everything has worked out very well, with excellent cooperation between Renewcell and Valmet. “Right from the start of the project, we had good discussions with Valmet about the installation solutions. Our focus was always on finding ways forward, and we appreciated the help of Valmet’s experienced team. We also sensed their curiosity about this new fiber, and how we could work with the equipment, so there was a shared dedication to making this succeed. I think everyone who gets involved in this project realizes how important it is for the environment and the future,” he says.

Renewcell conducted several pilot and lab trials at Valmet’s fiber technology centers in Finland and Sweden. Ari Saario, VP for Strategy and R&D for the Pulp and Energy business line at Valmet says of the cooperation: “Pilot trials play an essential role in reducing risks in technology development and upscaling, and I have to say I’m really impressed with the fast start-up of Renewcell’s first-of-a-kind plant. It’s also worth highlighting the importance of the close technology development connections we’ve enjoyed since the beginning of project – and even before then, in fact.”

The Renewcell site at Sundsvall, Sweden.

Circulose now moving into the market

Circulose is a high-cellulose dissolving pulp that can be used to make viscose, lyocell, modal, acetate and other types of regenerated fibers, which are sometimes called manmade cellulosic fibers (MMCF). These fibers are then spun into yarns or woven or knitted into fabrics and finally cut and sewn into high-quality new textile products.

The big difference with Circulose compared to traditional textile raw materials is that no new cotton, oil or wood is consumed. The recycled clothes, as well as other recycled textile waste streams, are shredded and processed into a dissolving pulp solution which is then bleached and dried. From there, it is delivered to fiber-producing customers in cotton sheets.

Joint solutions overcome challenges

As the Renewcell line at Ortviken was built in an existing building, a flexible layout was very important. The small Renewcell project team had many discussions with Valmet: “How should we do it with this machinery?” and “What kind of equipment do we need over there?” Valmet’s ability to advise on many of these questions was highly appreciated.

Circulose is a high-cellulose dissolving pulp that can be used to make regenerated fibers.

“As this is a completely new process,” explains Dahlbom, “we didn’t have a lot of people to ask about how to do it. To make progress, we had to invent a lot of things ourselves, sometimes with Valmet’s help. And we had global issues to contend with like the pandemic and the war that also affected the project. But we’re now moving well and ramping up production further, with a product that our customers can use, and that meets their high-quality specifications.”

“Fiber to fiber textile recycling is a new and extremely important field that answers very well to the circular economy goals. While the technology we have delivered is proven to work, unfortunately the whole textile value chain has not developed as expected which also impacts the financial viability of companies like Renewcell,” says Hanna Alarotu, Director, Global Sales, Pulp, Energy and Textiles.

Text Elin Boström and Åsa Arencrantz

Photos Torbjörn Bergqvist, Tomi Parkkonen, Renewcell

Valmet's delivery for Renewcell

Valmet supplied machine equipment, installation, commissioning, and technical support for:

- stock preparation

- bleaching

- pulp drying and baling – second-hand equipment.

Related articles