New era of efficiency and environmental performance

Dec 8, 2023

ARAUCO’s historic MAPA project faced several challenges but was ultimately a success. The energy efficient technologies, a high-power recovery boiler and a biomass boiler enable ARAUCO’s carbon neutrality and the delivery of renewable energy to the national electrical grid.

Having faced Covid-19 restrictions that led to special attention being paid to construction site safety and logistical planning, the project has certainly had its challenges. The good cooperation of all the parties has resulted in all the challenges being overcome. The production of the new line 3 started in January 2023, and an intensive ramp-up period is ongoing. ARAUCO expects the production from line 3 to be at full capacity by the first quarter of 2024.

We consider Valmet a strategic partner, and we’re united by friendship and respect.

“ARAUCO and Valmet have had a long relationship, and we consider Valmet a strategic partner. We’re united by friendship and respect, a result of the many years we’ve been working together,” says Hector Araneda, Operations and Environmental Manager of ARAUCO’s pulp business.

“The MAPA expansion project allows us to continue moving forward in line with our purpose and vision as a company,” says Hector Araneda from ARAUCO.

The total capacity of the Arauco mill will be as much as 2,100,000 tonnes per year of bleached eucalyptus kraft (BEK) pulp, of which 1,560,000 tonnes will be produced on line 3. The MAPA project is undoubtedly the largest ever made by the forestry sector in Chile.

A project in line with ARAUCO’s vision

“We decided to undertake this project for several reasons. MAPA allows us to continue moving forward in line with our purpose and vision as a company. We also wanted this growth to take place in the Arauco community, as we’re strongly committed to its development,” Araneda explains.

On Friday, January 20, 2023, the first bale of the new production line was celebrated

at Arauco Mill’s line 3.

“A new production line with the latest technology, which operates efficiently with the highest environmental standards to make products from a renewable raw material like wood, translates into greater productivity and leads to an increase in our competitiveness in the global market. The mill is in the process of ramping up, so there’s still a long way to go. However, we can already see interesting results in efficiency and performance in some areas, which make us optimistic about the future.”

Key technology islands supplied by Valmet included pulp drying and baling lines, a recovery boiler, a power boiler, mill-wide NCG solutions for odorous gas handling, and advanced automation and optimization solutions.

The new line 3 includes two pulp drying machines and four baling lines. The pulp drying line is characterized by low energy consumption and high availability.

“The equipment purchased from Valmet has met our basic expectations. Although MAPA has only been in operation for a few months, the balance is quite positive. From the operational perspective, we now have one of the most modern pulp mills in the world, operated by a highly qualified and committed team. We’re sure it will allow us to achieve the optimal operation of the mill and will be a determining factor in the future of the company and the community of Arauco,” Araneda continues.

An energy-efficient and autonomous line

The pulp drying and baling lines are characterized by their energy efficiency and high level of autonomy. The new line 3 includes two pulp drying machines and four baling lines.

All the machines in the four baling lines are built as independent units with all functions included. Valmet’s unique bale quality system and user-friendly touch screen displays help operators easily control, monitor and maintain the line.

“On one of the machines, we’ve already reached the designed production of 2,500 air dry tonnes per day, and we’ve been able to stabilize the other’s production and produce continuously without web breaks. The production is still being ramped up, but both machines have operated very well so far,” says Markus Laaksonen, Chief Site Advisor for Valmet’s pulp drying delivery.

Significant additional bioenergy production

The MAPA recovery boiler includes advanced safety and high-power features, and emissions are minimized with Valmet ESPs. The bubbling fluidized bed power boiler uses leftover biomass to produce additional steam and electricity. This enables the delivery of excess renewable electricity to the Chilean national grid.

We now have one of the world’s most modern pulp mills, operated by a highly qualified and committed team.

“Both the recovery and power boiler have performed well and can reach the nominal capacity. We’re still at the site supporting the ramp-up period and continuing to fine-tune the boilers,” reports Tapani Nummelin, Project Manager for the Valmet boiler delivery.

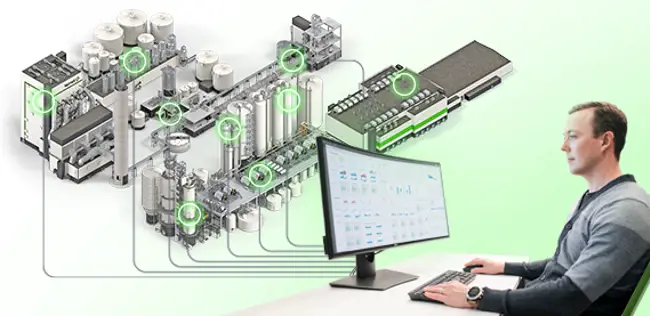

The most autonomous mill in the world

For the MAPA project, ARAUCO has invested heavily in technology, energy efficiency, and big data to make the processes more efficient. A comprehensive Valmet Industrial Internet services agreement was made to reach the next level. Expert support is given both on site and remotely through Valmet Performance Centers in South America and the Nordics.

The Arauco Mill line 3 is designed to become the world’s most autonomous pulp mill with Valmet’s Mill-Wide Optimization applications, advanced prediction and monitoring applications, as well as Valmet’s expert services.

“MAPA was designed to operate as an autonomous mill. To address this challenge, a complete training plan was developed for the operation and maintenance teams. To continue progressing in this challenge, we must consolidate the work of the teams involved. We aim to see the fruit of the autonomous operation in two to three years. We know this is a great challenge, and we also know that the contribution of autonomous operations to our results is very important,” says Araneda.

“ARAUCO is proud of this mill, where all the relevant considerations were incorporated to maximize the benefits for the company, including the safety of people, environmental performance, and efficiency in the use of resources,” Araneda concludes.

TEXT: Lotta Forssell and Kerstin Eriksson

PHOTOS: ARAUCO and Valmet

Earthquake-proof design

The project had special demands due to its location in an earthquake area. For example, all the main components are designed to withstand earthquakes. The electrical cabinets have lights on the outside that indicate if there is a voltage. The pulp drying and baling lines are installed on special earthquake-proof foundations, checked and certified by a third party. The dryer is supplied with special additional steel structures. In the recovery boiler, the steel structure is almost twice the weight of a similar boiler in the Nordics.

Community development

In conjunction with the MAPA project, ARAUCO agreed to carry out more than 30 projects defined in the citizen participation processes. These projects include the construction of a sewage treatment plant in Laraquete, rural drinking water projects in Horcones and Chillancito, and 11 neighborhood centers in various locations in the Arauco commune, and the launch of the DUOC UC Arauco campus, a superior education institution that seeks to educate professionals in the commune. Other investments include the delivery of nearly 1,500 houses to families in the area, the construction of the Horcones Nursery and new road access.

Related articles