Helen produces energy in a climate neutral way with a new wood pellet heating plant

Dec 18, 2020

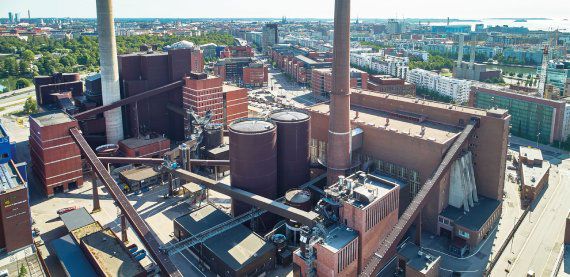

With its new wood pellet heating plant in the middle of the Finnish capital, Helen Ltd. is producing the best city energy in the world in a climate neutral way.

Helen, a company fully owned by the city of Helsinki with more than 500,000 customers throughout the country, aims to achieve 100 percent carbon neutrality in its energy production by 2035. The new pellet-fired heating plant at the Salmisaari site will enable Helen to significantly increase its renewable district heat production.

“Our old oil-fired peak load heating plant was reaching the end of its life cycle and had to be either modernized or replaced. Since our company’s goal is a carbon neutral energy system, we decided to go for a new plant that ran on renewable energy,” says Aleksi Nurmi, Project Manager at Helen.

The Salmisaari lot is small, and a pellet-fired plant requires less storage space than one that runs on wood chips, for example. “Additionally, we’ve been combusting pellets with coal in our Salmisaari B power plant unit, so we already had a pellet reception system and storage silos, which made the investment easier.”

We wanted a turnkey delivery from a supplier who could deliver a complete plant.

The largest pellet-fired boiler in Finland

Valmet was chosen to supply the boiler plant through a public tendering process. “Among the candidates, we regarded Valmet as a good and reliable supplier, because we’ve cooperated with the company before and knew they had the capability of supplying such solutions,” Nurmi points out. “Since we knew that the combustion of wood dust was challenging, we absolutely wanted a turnkey delivery from a supplier who could deliver a complete plant.”

Hammer mill grind the wood pellets into a fine dust. All the wood dust particles need to be below 1 mm to provide efficient and stable combustion.

Valmet’s delivery included fuel conveyors from the existing storage silos, wood pellet grinding and wood dust equipment, a hot water boiler and a bag house filter for flue gas cleaning. Valmet was also in charge of the plant construction and electrification, as well as supplying a Valmet DNA automation system that was integrated with the existing plantwide Valmet DNA automation system.

With a fuel capacity of 100 megawatts (MW) and a district heat output of about 92 MW, the pellet-fired boiler is the largest of its kind in Finland. The amount of district heat that the plant produces is enough to meet the heating needs of 25,000 one-bedroom apartments.

The plant’s location in urban surroundings calls for efficient dust emission control. According to Pesonen, the plant’s dust emissions are at a very low level thanks to the bag house filter.

“Very pleased with plant performance”

The new boiler plant was started up in late 2017. During the first heating season, pellet grinding proved more complicated than had been expected, leading to Valmet deciding to change some technology components in the spring of 2018. These setbacks prolonged the project and postponed the handover from what the original plan had envisaged.

“In spite of the challenges, our cooperation with Valmet during the project has been good, and we’ve been able to come to an understanding about everything. Valmet has proven a reliable supplier and has met our expectations,” Nurmi remarks.

The performance tests were run during the 2019–2020 heating season. “We were able to achieve all the plant warranty values, and are very pleased with the test results and plant performance,” adds Sami Pesonen, Process Engineer at Helen.

Let’s hear Valmet’s side of the story, too: “This was a long and challenging project, during which we gained a lot of new knowledge about pellet combustion. At no point did we leave the customer alone – we bore our responsibility for the delivery to the very end,” comments Jouni Valtatie, Product Manager, Pellet Plants, Valmet.

Toward networkwide optimization

In 2019, Valmet and Helen agreed the supply of an optimization solution for Helen Ltd.’s district heat production and network in Helsinki, Finland. Optimization is one of Helen’s tools for achieving 100 percent carbon neutrality in its energy production. The Valmet DNA District Heat Manager enables the management of district heat production, consumption and transfer with a single solution. “The optimization system, which predicts transmission delays and temperatures, will improve the energy efficiency of the entire district heating network, because it can be used more optimally. This change in our operating model will reduce energy procurement costs and therefore emissions,” says Miika Lindholm, Group Leader, Helen.

The architecture of the new pellet plant blends in seamslessly with the older Salmisaari power plant buildings.

Did you know that Göteborg Energi is building an even larger pellet-fired district heating plant based on Valmet’s technology in Gothenburg? The boiler will have a fuel capacity of 130 MW.

Text Marjaana Lehtinen

Related articles