Sky-high efficiency at Helen with Valmet’s heat recovery and pump technology

At Helen’s Vuosaari bioenergy heating plant, Valmet’s solution combines flue gas condensation and combustion air humidification with heat pump technology, driving the overall plant efficiency beyond 120 percent and the stack temperature to 11°C.

In an era when environmental sustainability and energy efficiency are paramount concerns, industries and residential sectors are increasingly seeking innovative ways to maximize their energy efficiency and reduce their carbon footprint.

Heat recovery increases plant efficiency to about 122 percent based on the fuel’s effective heating value.

Helen Ltd., one of the largest energy companies in Finland, is doing this, too. It is phasing out coal and aiming for carbon-neutral energy production by 2030. Its Hanasaari coal-fired power plant was closed in April 2023, and its Salmisaari coal-fired power plant will be closed in 2025. Heat production at these power plants will be replaced by recycling excess heat with heat pumps, as well as by using biomass and heat storage.

The absorption heat pumps at Helen’s Vuosaari bioenergy heating plant.

In late 2022, Valmet started up a flue gas condensing plant and condensate treatment equipment, including a boiler make-up water production system, at Helen’s Vuosaari bioenergy heating plant.

Optimizing heat recovery with heat pumps

By combining its heat recovery process with condensate treatment, Helen can reduce freshwater consumption, promote the circular economy and gain water bill savings. In turn, combustion air humidification has a profound impact on the plant’s combustion process. It increases the temperature at which water vapor in the flue gas condenses, improving the entire system’s efficiency. This allows a more substantial recovery of latent and sensible heat, which, when coupled with the benefits of heat pumps, results in a cascading energy recovery effect.

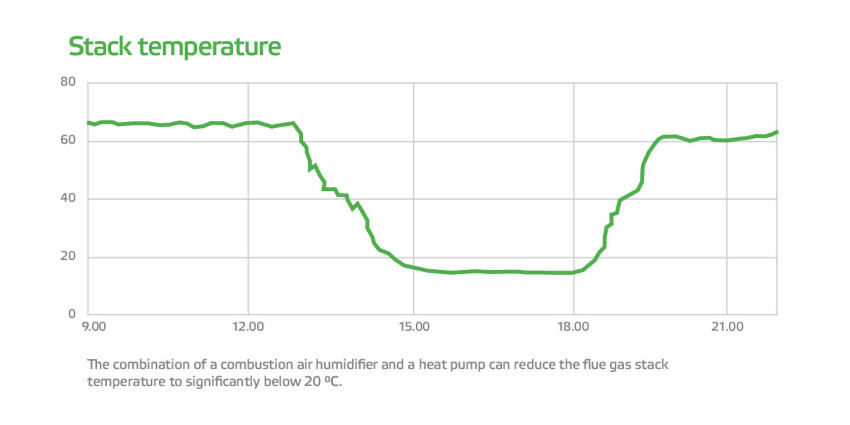

The optimized process can push the stack temperature significantly below 20 °C.

To maximize Helen’s overall plant efficiency and heat recovery for their district heating network, Valmet developed a novel solution which combines traditional flue gas condensation and combustion air humidification with absorption heat pumps.

Description automatically generated

Heat pumps extract heat from a low-temperature source and transfer it to a higher-temperature destination. Typically, a heat pump increases efficiency by cooling an incoming district heating waterflow and transferring the heat to a waterflow after the condenser heat recovery. However, while decreasing the incoming flow allows a higher temperature difference for condenser heat recovery, it reduces the heat and humidity available for the combustion air humidifier.

“Flue gas condensation and heat recovery combined with combustion air humidification and a heat pump are cutting-edge technologies that harness the potential of waste heat from combustion processes, contributing to energy savings and reduced emissions,” says Lari-Matti Kuvaja, Director, Environmental Systems, at Valmet. “While traditional heat recovery with condensation can reach stack temperatures of close to 50 to 60 °C, our optimized process can push the temperature significantly below 20 °C. Recent concept calculations at our customers’ plants have approached single-digit temperature readings.”

“Flue gas condensation and heat recovery combined with combustion air humidification and a heat pump are cutting-edge technologies that harness the potential of waste heat from combustion processes,” says Lari-Matti Kuvaja, Director, Environmental Systems.

Finland’s most efficient heat recovery plant

Helen’s Vuosaari bioenergy heating plant now features very high energy efficiency. The heat recovered from flue gases increases district heat production by 69 megawatts.

Energy efficiency has been taken to the highest level, and the minimum temperature of the flue gas it produces is about 11 °C when it leaves the stack. The heat recovery from flue gases after the boiler is maximized, and almost all the water vapor the gases contain is condensed with the aid of a separate heat recovery plant.

Valmet’s patented technology makes the Vuosaari bioenergy heating plant the most energy-efficient heat recovery plant in Finland. Water vapor accounts for less than 1 percent of the flue gas mass leaving the stack, and the utilization of the entire plant calculated according to the method used in the EU is a whopping 122 percent.

The combination of a combustion air humidifier and a heat pump can reduce the flue gas stack temperature to significantly below 20 °C.

“Valmet’s solution of using absorption heat pumps at this scale to utilize all the available heat has helped Helen maximize the overall efficiency of the entire Vuosaari bioenergy heating plant. The heat recovery solution also increases the condensate production, from which Helen produces make-up water for the Vuosaari plants and the district heating network, thus reducing Helen’s city water consumption,” says Timo Kuitunen, Project Manager at Helen.

Expert support for smooth operations

In June 2023, Helen and Valmet signed a service agreement to support the smooth operation of the flue gas condensing plant at Helen’s bioenergy heating plant in Vuosaari, Helsinki. Under the service agreement, Valmet delivers expert services to support the customer in attaining optimal equipment performance.

“Valmet is this plant’s original supplier, and as it’s the first of its kind for Helen, we want to ensure a successful commissioning by working with Valmet for at least the first couple of years. We expect to receive expert service during the agreement period and to learn how to operate and maintain the plant in the best possible way ourselves. I’m very confident that our partnership with Valmet will go smoothly,” adds Kaj Luukko, Asset Manager at Helen.

With Valmet’s support, Helen can concentrate on its core business of operating the plant and delivering heat to the Helsinki area’s residents.

Text Lari-Matti Kuvaja, Marjaana Lehtinen

Related articles