100% electric ferry Ellen trusts in Valmet’s automation

Feb 28, 2023

An ambitious project for an electric ferry in the Danish archipelago started in 2017 and was financially supported by the European Union. Many innovative suppliers participated in the project, including Valmet.

Pollution-free water transportation to islands

The European Union’s Horizon 2020 research and innovation program was a success. One of the targets was to create a ferry with no emissions. It involved the design, building and demonstration of a fully electric-powered “green” ferry that operates with no pollution or CO2 emissions.

The Danish island of Ærø aims to be fossil fuel free by 2030 and CO2 neutral by 2025. Already now, the municipality has four ferries in operation – and one of them is Ellen, the e-ferry.

Automation supports sustainable sailing

The Valmet DNA integrated automation system covers the control, alarm and monitoring of machinery systems as well as the electric propulsion drives and bow thrusters. The entire crew, engineer Johan Friderichsen, captain John Tuft and captain Martin Christoffersen, know the automation system very well.

Both of the captains have experience in sailing worldwide for years. Now, they are proud to be back in Denmark and part of making sailing history – operating the first e-ferry and eagerly sharing their knowledge.

“We are such a small team. Everybody’s hands-on approach is needed. We have to move fast when arriving in the harbor or when leaving the port. For all these events, we have a brilliant automation system with many features to take care of and support our operations,” Martin describes.

Matti Nurminen is an experienced chief engineer from Valmet and has been involved in several maritime projects. He remembers this project well with the e-ferry. “I feel it was pioneering work for all of us. We learned a lot when cooperating with the stakeholders and building the largest e-ferry in the world together. It formed a great base of knowledge for following similar projects,” Matti describes.

Martin praises the versatility of Valmet’s automation. “All relevant information is available to make our sailing safe and sustainable. We can see the temperature of the cooling water. We are able to handle the ballast water and be aware of the tank levels. And we can clearly follow our energy consumption on the user-friendly displays,” he states.

Safety is trusting automation

Safety is extremely critical on a passenger ferry. Since the process controllers are fully redundant, the automation system, too, contributes to safety.

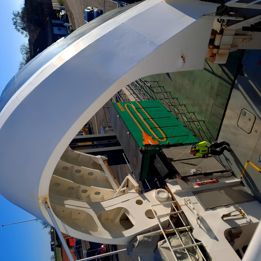

“We have expensive cargo on board – passengers, pets, vehicles, goods – sometimes even cattle are transported to slaughterhouses. Today, there was a lady with a therapy dog used in caring for elderly people and teenagers. No two days are the same in terms of cargo or climate,” Martin says.

The ferry can transport 31 cars, or alternatively, five trucks. The vessel has capacity for 198 passengers.

John explains: “Through Valmet DNA, we are informed and notified of alarms, if needed. The system controls and monitors lights, the sun deck, doors and much more.”

The two battery rooms are essential on the ferry. The batteries were developed by the Swiss company Leclanché and are placed in two different rooms. The total capacity covers 4.3 MWh. The charging arm located in the port of Søby handles recharging while the ferry is being loaded. Danfoss Editron has delivered the engines to the ferry.

|

|

“Even the charging is handled with the automation system. Once the charging connection is created, the arm is connected. After charging, the arm is disconnected. We are able to see the available energy and consumption on the Valmet DNA screens,” Martin explains.

Data available in beautiful surroundings

The main operator station is located on the bridge where the crew has the best views out to the sea. Every day, every season brings new seascapes. “This is the best working environment ever!” John says.

In addition, there are operator stations outside of the battery rooms and a viewer station in the mess room.

Vital process data and alarms are stored in the history server. Especially those alarms that need the crew’s attention are classified as critical. Furthermore, the information can later be analyzed to learn more about best practices.

“I consider Valmet DNA to be very reliable. The availability of the system is great. We have never had any problems with it. We could not sail without it. It offers us peace of mind on a busy day,” Martin confirms.

Nature thanks Ellen

Ellen is an emission-free green ferry when operating with wind and solar energy, which saves about 2,520 tons of CO2 annually. When charging with the ordinary electricity network on a day with no wind or sun, the vessel reduces CO2 emissions by around 2,010 tons of CO2 per year, according to the ferry’s evaluation report.

World record achieved

One trip to Ærø and back to Als is 22 nautical miles, which is about 40 kilometers. Recently, Ellen made its record journey by traveling 50 nautical miles, which is about 92 kilometers. This set a world-record voyage on a single battery charge.

It was a journey to Sønderborg, Denmark, and passengers included industry leaders, government members and members of the 7th Annual Global Conference on Energy Efficiency. The record-breaking journey has been submitted for publication to the Guinness World Records.

Along with other suppliers, Valmet is proud to be part of the success – together with Ellen and her crew.

For more information:

Heikki Tanner

heikki.tanner (at) valmet.com