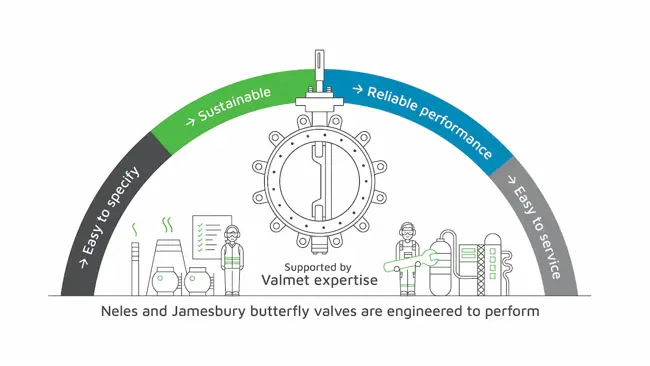

Navigating high temperature challenges with Neles™ Neldisc™ butterfly valves

As process temperatures go up, the challenges for the flow control equipment increase gradually. Stepping above 250 °C requires most of the plastics and polymers to be abandoned and the selection of metallic materials instead. Furthermore, when the temperature rises above 600 °C, the challenges with the suitability of the materials require even more careful attention. Understanding high temperature needs becomes crucial for safe and reliable plant operation, because automated valves often play a key role in process control.

Pushing the boundaries: Beyond 600 °C

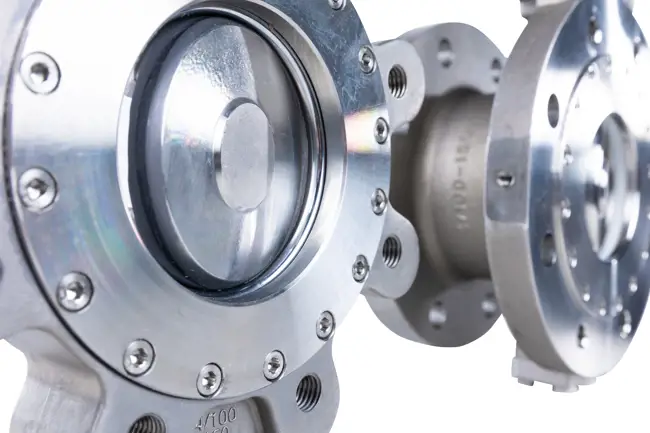

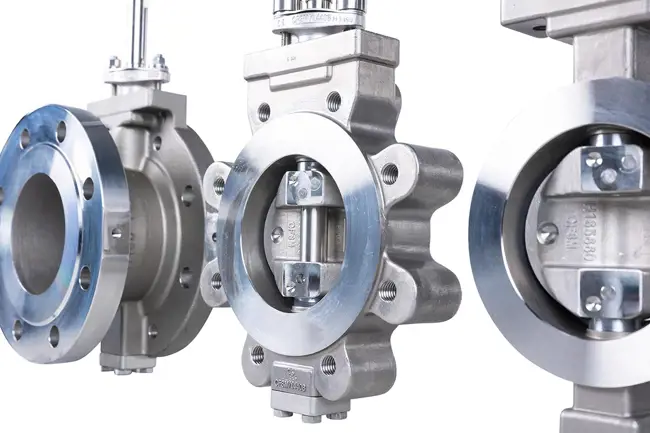

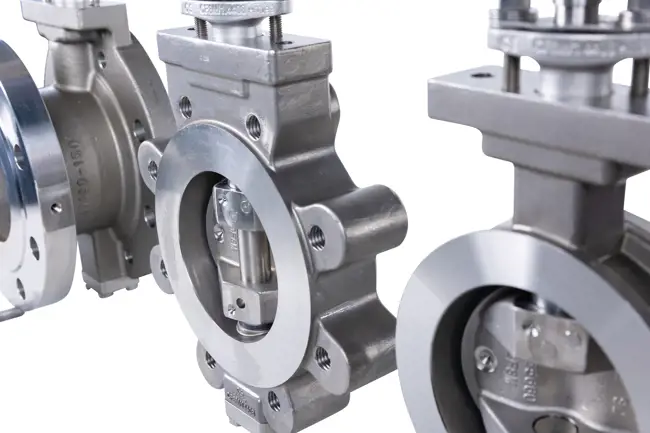

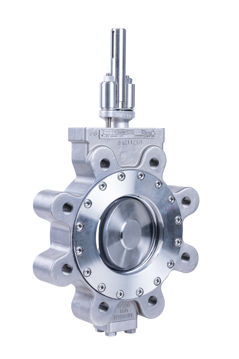

Proficient material selection is an inevitable starting point, but temperatures above 600 °C may also require certain construction changes compared to lower temperatures. Adjustments to bolting, sealing materials and the design of a shaft extension to move shaft seals and actuators away from the intense heat may be necessary. Many widely used sealing materials such as graphite are no longer suitable for elevated temperatures, but full-metal solutions are required. Neles™ Neldisc™ metal seated triple eccentric high-performance butterfly valves are an excellent selection for a high-temperature service, as the construction is proven in use in several different types of applications involving elevated temperatures. Neldisc valves also offer a versatile option because they can handle both control and tight shutoff applications. This simplifies the equipment selection and also offers a benefit from the spare part and service perspective.

Increasing the challenge level with big temperature swings

Process challenges are not always limited to high temperatures, but abrupt temperature changes may also occur. Heavily fluctuating temperature places an even higher demand on process equipment, as it underlines the compatibility of different materials – not only at one given temperature but in a large operating window. One straightforward approach would naturally be to use as much selected material to ensure the equal thermal expansions of parts during process condition changes. However, limiting the selection to only one type of material rarely provides an optimal solution for the plant operator, as such limitations often mean tradeoffs in the performance, tightness or endurance of the product.

The superiority of the Neles™ Neldisc™ metal seated triple eccentric butterfly valve culminates in the full-metal seat and one-piece disc. Their seamless association makes these valves a perfect fit for a high-temperature service. The seat ring is self-centering, meaning that it can move in a plane perpendicular to the pipeline, ensuring the disc is always optimally accommodated. At the same time, the seat ring automatically adjusts itself upon steep temperature changes to provide a tight shut-off at elevated temperatures as well. The self-adjusting feature ensures the disc does not jam against the seat when temperature fluctuations occur. It therefore offers uncompromised reliability and takes the process safety to the level it needs to be at in extreme conditions.

Discover more on the topic

Subscribe to our newsletter

Subscribe now to our 'Go with the flow' newsletter and receive the latest insights directly to your email.

Subscribe