What is the history of Neles™ valve controllers?

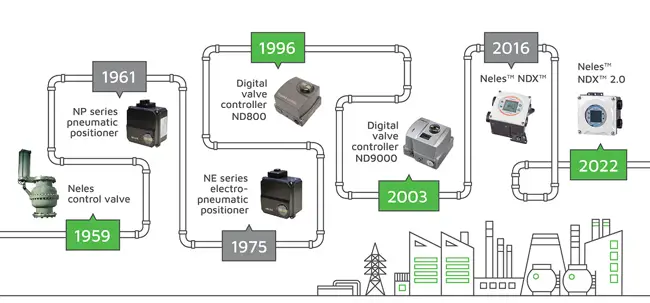

We have a strong background in providing valve controllers for the pulp and paper industry. For the last 60 years, we have been delivering best-in-class valve controllers for pulp factories. Then for the last 20 years, we have been growing as a global provider of valve controllers for a variety of industries.

About 10 years ago, we started the design work for the new generation Neles NDX™ 2.0 valve controller. I’m happy to say that this work has now resulted in a versatile valve controller product for all industries and applications.

How has the Neles NDX development moved forward?

With the Neles NDX, we had the first release in 2016 and since then, we have been developing the offering to meet the needs of different industries. We have been building incrementally on a steady foundation of our reliable core technology and robust design.

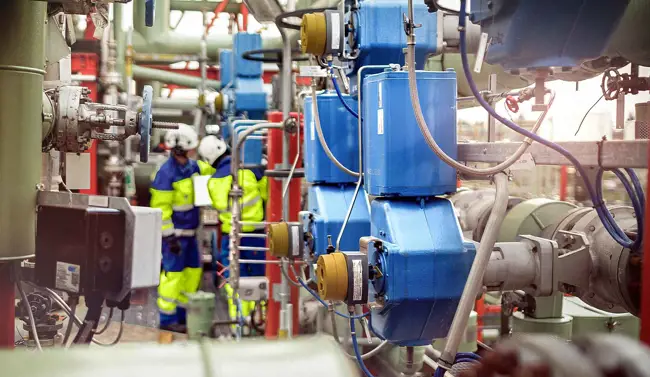

The Neles NDX 2.0 has universal performance, meaning it can be put on top of any valve or actuator.

The next generation valve controller Neles NDX 2.0 has been designed to meet the needs of varying markets and industries, like petrochemical, chemical, and oil and gas. It has universal performance, meaning it can be put on top of any valve or actuator. It provides interoperability to the most common automation systems. In addition, we have been developing the usability and simplicity of the controller based on customer feedback. These developments enable safer and even more reliable day-to-day operations.

How is Valmet taking sustainability into account?

The pneumatic relay consumes 80-90% less air than the previous generation controllers.

Sustainability is at the core of our offering. We have designed the pneumatic relay of the Neles NDX 2.0 so that it provides a win-win-win solution for our customers, Valmet, and the environment. The pneumatic relay consumes 80-90% less air than the previous generation controllers. This can lead up to 0,5M€ and above annual savings in operational expenses at larger plants based on our installed base analysis. Through lower air consumption, the Neles NDX 2.0 uses less electricity during its lifecycle which also results in lower carbon dioxide emissions.