Keeping it safe and clean with Valmet Drone Services for tissue producers

May 14, 2021

The newly launched Valmet Drone Services offers intelligent cleaning and inspection solutions for tissue mills and other production areas. With the help of furnished drones, the site can be cleaned and inspected with ease – resulting in a dust-free and safe working environment.

Dust accumulation can cause quality and safety hazards at tissue mills and other production sites. Falling dust can lead to sheet breaks or the contamination of finished products, and dust also creates a major risk of machinery fire.

To help customers keep their working environment clean and safe, Valmet has developed innovative and intelligent solutions that utilize commercial drones for cleaning. Paul Arnold, Product Sales Manager at Valmet, and his team have been responsible for the product development.

“From the outset, we’ve collaborated with several customers to identify the real bottlenecks in keeping the production site clean. As a result, we’ve now launched two different solutions that meet our customers’ needs. An automated cleaning solution with blowers is suitable for areas with a small fire risk, and one with vacuum suction for more delicate areas where blowing is not advised. We offer both a full cleaning service with operator services and an option for renting the drones, including comprehensive training and full technical support for the entire period,” Arnold explains.

Drone an agile tool

Removing dust is a must, but manual cleaning using a manlift or ladder creates a safety risk and requires a machine shutdown. Many dusty areas are also difficult to access or reach with vacuums. A normal cleaning routine is run every week in the converting area and every three months in the machine building.

Transferring to drone-aided cleaning increases safety and reduces downtime.

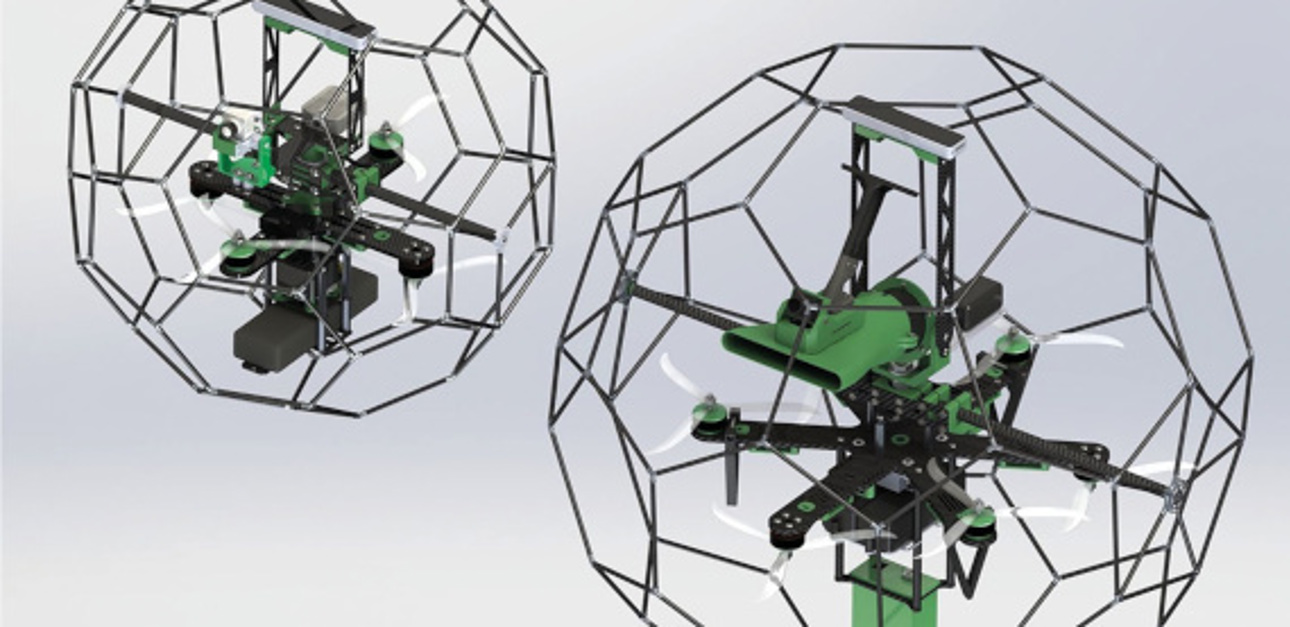

“Transferring to drone-aided cleaning offers many benefits for our customers. It increases the safety of the working environment, because the operators don’t need to enter the machine parts for cleaning, and it also reduces downtime, because the powerful blowing power offers faster cleaning than manual vacuuming. The drone’s small size means numerous position control features, frame protection and redundant controls that can agilely access tight areas,” Arnold says.

More to come

At first, Valmet Drone services will concentrate on cleaning solutions. To broaden the offering, development projects are already ongoing for utilizing drones in other services.

“The same technology can definitely be used for many purposes besides cleaning – inventory counting, measuring bulk storage volume and tank inspection are just some examples,” Arnold concludes.

Text Marianne Valta

Photos Paul Arnold

Valmet Drone Services development started accidentally

The original idea behind harnessing drones for Valmet’s on-site services was sparked when Paul Arnold, Product Sales Manager, wanted to document a newly installed pulp bale dewiring project. The machine part was covered with dust, and to create better pictures, the photographer, who was operating a drone, offered to clean it using its blowing feature. After less than five minutes, the area was clean – and the idea was born.

“Our team started to develop the idea further with several customers. The services have been designed to meet actual customer needs, and the offering so far includes two different solutions: the automated cleaning solution with blowers and the cleaning solution with vacuum suction,” Arnold says.