Success with the Valmet Acoustic Pyrometer at the Xinyuan Power Plant

Oct 9, 2020

The continuous furnace temperature measurement during the full load is a difficult problem. On the 700MW supercritical boiler furnace at the Xinyuan power plant in China this has been solved with the installation of a Valmet acoustic temperature measurement system.

Summary

| Location | Xinyuan, China |

| Customer challenge | Continuous measurement of the furnace temperatures during the full load. |

| Solution |

Valmet Acoustic Pyrometer, an acoustic temperature measurement system. The system provides a large amount of data on furnace combustion conditions and flue gas temperature distribution. |

| Results |

|

| Keywords | Valmet Acoustic Pyrometer, Automation, China |

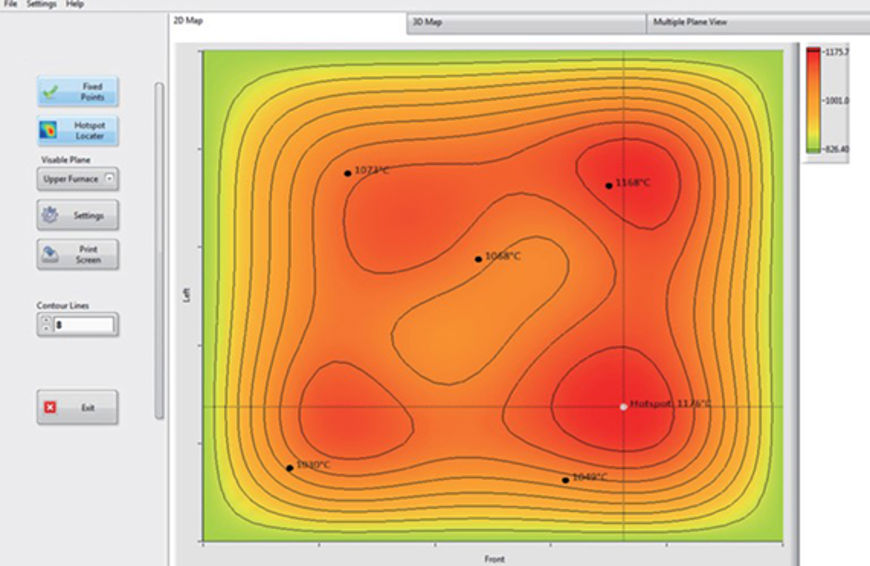

2D Temperature field distribution. The system utilizes 2 acoustic generators (ASG) and 8 acoustic receivers (ASR) to determine the temperature distribution in 16 zones of the furnace outlet. The 16 zone temperature information and a 2D temperature field distribution are presented on a control room screen for operating personnel to make the correct adjustments and optimize combustion conditions.