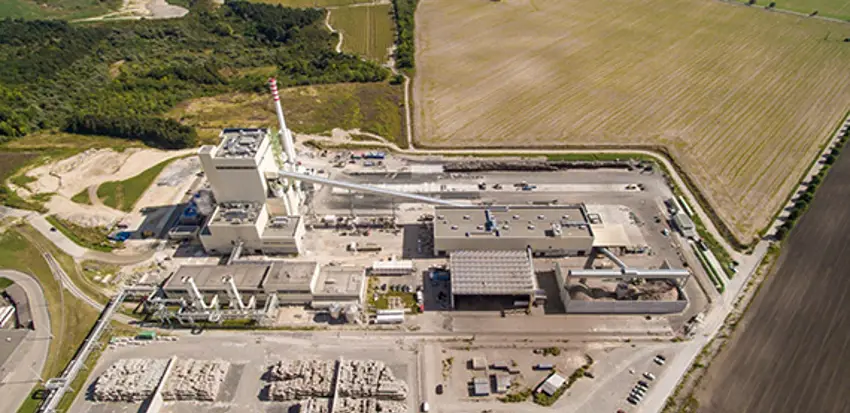

High-efficient and sustainable energy production at Hamburger Hungaria`s power plant

Sep 13, 2017

Hamburger Hungaria's new power plant produces electricity and steam for Hamburger Hungaria's containerboard mill that operates two paper machines. It has replaced the existing gas-fired boiler plant that produced steam only. With Valmet CFB Boiler (formerly CYMIC), utilizing circulating fluidized bed technology, Hamburger Hungaria Power has now capability to use a wide range of solid fuels, biomass, coal as well as recycled containerboard rejects and sludge, in energy production instead of natural gas.

Summary

| Location | Dunaújváros, Hungary |

| Customer challenge | To secure uninterrupted energy supply for the containerboard mill and high fuel flexibility. |

| Solution | Valmet CFB Boiler, Flue gas cleaning, Valmet DNA automation system, Service agreement |

| Results |

Co-generation plant can handle all rejects from the containerboard making process while providing the mill with steam and electricity. |

| Keywords | Energy, Europe, CFB boiler, CYMIC, Flue gas cleaning, Automation system, Service agreement |

Technical data

| Steam | 158 MWth 62 kg/s 113 bar 520°C |

| Fuels | Biomass, coal, rejects, sludge |

| Start-up | 2015 |