The first choice for kraft mills pulping softwood and hardwood

Valmet Continuous Cooking is a technologically advanced system for more sustainable and cost-effective pulp production. It is the first choice for kraft mills pulping hardwood (eucalyptus, acacia, birch etc.), softwood (pine, spruce etc.) or bamboo.

Effective impregnation with Valmet ImpBin

Two-vessel system providing uniform high yield pulp

High flexibility with unique control of liquor to wood ratio

A simplified, easy to operate system with a cost effective layout

The evolution of continuous cooking

Since the first commercial order in 1948, the Valmet Continuous Cooking System's evolution has yielded a plethora of groundbreaking innovations. The latest advancements in digester technology leverage cutting-edge research, with a core focus on streamlining the cooking process, giving rise to the Valmet Continuous Cooking concept.

This streamlining effort has had a profound impact, significantly reducing both the initial investment and ongoing operational costs. Additionally, it has introduced heightened flexibility and simplified operational procedures as notable advantages. The development endeavor also encompasses an improved layout, enhancing aspects such as pipe length, accessibility, and maintenance.

Impregnation at low temperature for a long time

Valmet ImpBin™ chip impregnation system establishes a thorough impregnation of the chips with liquor before cooking. The atmospheric Impbin combines the basic features of the traditional chip pre-steaming bin, impregnation vessel and flash system. Impregnation of chips at low temperature for a longer time has proven to be very effective generating pulp with very low reject content. Effective impregnation in combination with the benefits of Valmet’s continuous cooking process produce pulp with high yield and excellent quality.

Process flexibility allowing the liquor to wood ratio to be controlled in a unique way

Valmet’s continuous cooking process chemistry is a further development of the “four rules of Kraft cooking” originally developed at STFI and the Royal Institute of Technology. The Continuous Cooking system is a very flexible process allowing the liquor to wood ratio to be controlled in a unique way during the various parts of the cooking process.

This added process flexibility allows the alkali profile to be optimized achieving a more selective cook with less carbohydrate degradation resulting in better pulp quality and higher yield. Valmet’s continuous cooking process re-circulates black liquor to the impregnation and cooking stages. As a result the hydrogen sulphide concentration is increased during the impregnation and cooking stages. By optimizing the hydroxide and increasing the hydrogen sulphide concentration it has been possible to increase the selectivity of the Kraft process in the initial cooking phase, the bulk delignification stage, and thereby decreasing the amount of slowly reacting residual phase lignin. The above has led to an increase in the rate of delignification in the bulk phase which is utilized to decrease the cooking temperature. Decreasing the temperature minimizes carbohydrate degradation and strength losses.

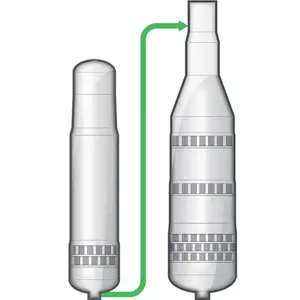

The benefits of a two-vessel system

The Continuous Cooking system design is based on results from the latest research on delignification chemistry. Benefits of a two-vessel system compared to a single-vessel are many. A two-vessel system has no radial temperature and alkali concentration variations, well defined impregnation zone, simple liquor to wood ratio control of the different cooking zones, recirculation of black liquor to the impregnation phase for process benefits.

Related videos

Material for download |

||

|---|---|---|

| Valmet, the technology leader in cooking | PreHyd – The ideal rebuild option for dissolving pulp | The Art of Cooking |

Our expertise is at your service

Using our contact form you can send inquiries, give feedback, request information and ask questions.

Contact us