Valmet Calender Roll Cover CL-EC for extreme calendering

Mar 29, 2016

Based on Valmet Calender Roll Cover CL, this EC (Extreme Conditions) cover provides increased durability for very high load/speed calenders. As with the standard CL cover, CL-EC provides extremely high wear and barring resistance in physically demanding or barring-ridden calender positions.

The need for more durability

The dynamic loading of the calender nip requires the most of a cover material. Fast nip deformation at high stress levels and high frequency can only be endured by a combination of optimum material selection and cover structure design.

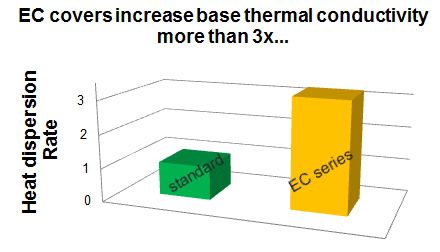

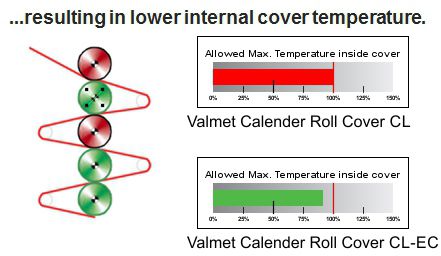

The soft cover material needed for a suitable nip width has a natural tendency to generate heat under repeated nip loading. Higher cover temperature reduces the cover durability.

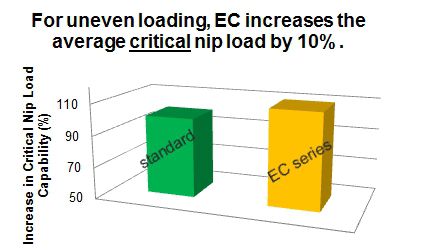

The loading in the nip is never uniform, either from intended local loading (zone-loaded roll), from non-uniform roll structure (stiff roll ends), or from non-uniform paper properties. Local loading leads to local heat generation. Local heat generation can lead to hot spots.

By improving cover thermal conductivity the cover behaves more uniformly and can better withstand non-uniform calendering conditions.

Valmet Calender Roll Cover CL-EC is suitable for supercalender polymer, calender DC and calender intermediate/polymer roll positions. It features excellent resistance to all normal process and cleaning chemicals.

Benefits

- Very durable hot spot resistant cover for the most severe calendering conditions, such as very heavy load and high speeds

- Cost savings from long, reliable runs, especially in barring-ridden calenders

- Long regrinding intervals, resulting in less need for roll changes

- Smooth surface for good paper quality

Specifications

- Material: Composite

- Colour: Blue-green

- Hardness: 92 ShD

- Surface roughness: Ra < 0.6 μm / 25 μin

- Thickness: 11-20 mm / 0.43-0.75 in.

- Doctoring: Carbon fiber or glass fiber blades are preferred (ValEco 4.1 or 10.1), oscillation needed.

Valmet's EC series covers are running under the most severe calender conditions possible, in multi-nip calenders for release paper at extreme high load and temperature. With over 15 covers delivered and running successfully in North America and Europe, Valmet Calender Roll Cover CL-EC is proving its value.

For more information on improving your calender roll durability and cover lifetime, contact your Valmet representative.