Broke pulping

High availability, optimized cost

- Flexibility for process fluctuations

- Proven designs, tailored for all stages of broke collection

- Trouble-free operation

Well defiberized broke

- Pulping of all paper, board, coated and special grades as well as slabs

- Efficient deflaking with energy saving rotor

- High pumping effect

Easy operation

- Easy to use - simple process control

- Low maintenance requirements

- Low vibration and noise levels due to the isolation ring between the rotor unit and pulper vat

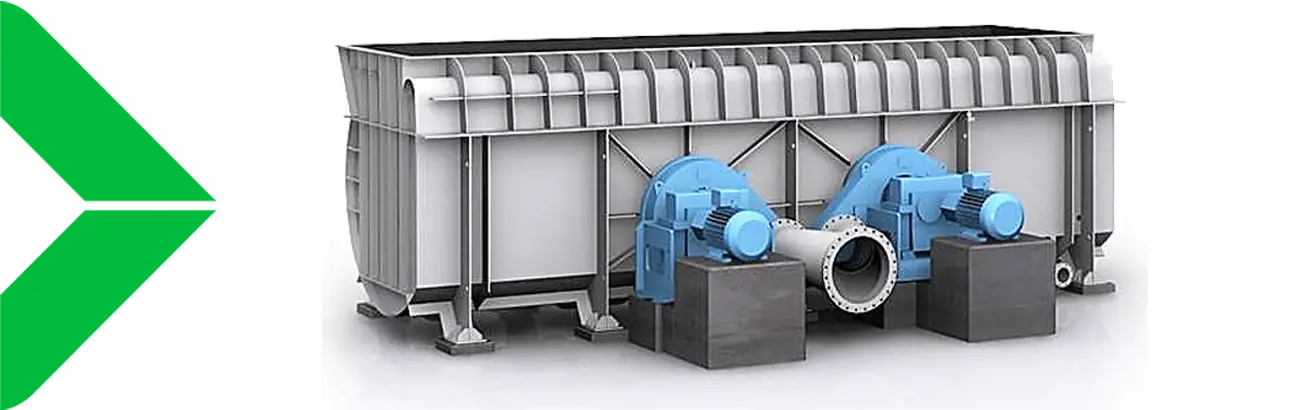

Valmet Broke Pulping Solutions

The extensive reference base of Valmet’s Broke Pulping Technology confirms the success of the Valmet Broke design for a wide range of applications. Combined with a special rotor design, Valmet Broke Pulpers deliver high pulping efficiency in all broke pulping applications.

Energy-efficient rotor unit

The Valmet Broke Pulper rotor delivers a high pumping effect with efficient defiberizing at low energy levels. The standard rotor produces active circulation with pumping vanes, while a sawtooth rotor is used to slush wet-strength, board, coated and special grades, as well as slabs. Extraction and deflaking plates under the rotor are used to deflake and screen the broke to the desired quality level.