Stonel™ Hawkeye™ HX

Proximity sensors for linear valve position sensing in hazardous locations

The explosionproof Stonel Hawkeye, with its stainless steel enclosure, is designed for service in harsh process environments. It features a solid state proximity sensor which is encased in a shock absorbent urethane potting material. Outputs for universal switching or NAMUR (EN 60947-5-6; I.S.) are standard options.

Features

-

Extremely durable and corrosion resistant.

-

Stainless steel washers and fasteners

-

Solid state magnetic sensor

-

Sensor is urethane sealed in a module

-

1/2” NPT, M20 or Cable Gland with 6-foot cord length

Specifications

|

HX35:

|

Universal voltage switching

|

|

HX45:

|

Namur sensors (5-29 VDC)

|

|

Temperature range:

|

-40 °C … +80 °C / -40 °F … +176 °F

|

|

Material:

|

316 stainless steel

|

|

Hazardous area approvals:

|

Ex i, Ex d, Class I, Division 1, Class I, Division 2 see Approvals tab

|

Downloads |

||

|---|---|---|

| Hawkeye brochure (Stonel branding) | Installation manuals | Bench test diagram |

| Hawkeye HX dimensional drawing | Hawkeye HX stp file | |

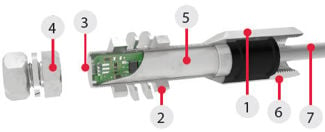

1. 316 stainless steel enclosure is extremely durable and corrosion resistant.

2. Stainless steel washers and fasteners included with HX enable secure vibration resistant mounting.

3. Solid state magnetic sensor detects trigger at distances up to 6 mm (extended sensing range also available).

4. Magnetic trigger is embedded in the included stainless steel bolt.

5. Sensor is urethane sealed in a module which is additionally sealed within the stainless steel 6. enclosure assuring high tolerance to shock and vibration.

6. Common Conduit/connector options (½” NPT, M20 and cable gland) are available with standard 6-foot cord lengths allowing flexible wiring options.

7. No seal offs are required with explosionproof conduit systems reducing installation costs.

8. Suitable for most hazardous locations explosionproof, flame proof Div 1/Zone 1; intrinsically safe Div 1/Zone 0; nonincendive Div 2/Zone 2.

Speed installation with LED indication

Linear applications

The Hawkeye HX is designed for valve position indication for linear valves like gate valves and globe valves. The HX is suitable for hazardous locations using Explosionproof / Flameproof protection concepts.

1. 316 stainless steel enclosure is extremely durable and corrosion resistant.

2. Stainless steel washers and fasteners included with HX enable secure vibration resistant mounting.

3. Solid state magnetic sensor detects trigger at distances up to 6 mm (extended sensing range also available).

4. Magnetic trigger is embedded in the included stainless steel bolt.

5. Sensor is urethane sealed in a module which is additionally sealed within the stainless steel 6. enclosure assuring high tolerance to shock and vibration.

6. Common Conduit/connector options (½” NPT, M20 and cable gland) are available with standard 6-foot cord lengths allowing flexible wiring options.

7. No seal offs are required with explosionproof conduit systems reducing installation costs.

8. Suitable for most hazardous locations explosionproof, flame proof Div 1/Zone 1; intrinsically safe Div 1/Zone 0; nonincendive Div 2/Zone 2.

Speed installation with LED indication

Linear applications

The Hawkeye HX is designed for valve position indication for linear valves like gate valves and globe valves. The HX is suitable for hazardous locations using Explosionproof / Flameproof protection concepts.