Taking the circular economy forward – Improved use of resources

Valmet has an important role in the circular economy by offering customers technology and services for converting renewable resources into sustainable products, such as pulp, paper, board and bioenergy.

One of our focus areas to enable circular economy for our customers is resource efficiency where our solutions for paper, board and tissue production aim at improved and optimized use of resources.

Resource efficiency can be improved through technology, automation and maintenance. Significant savings in energy, water and raw materials can be achieved through Valmet’s technologies, such as OptiConcept M paper and board machines as well as Advantage NTT tissue machines.

OptiConcept M – a modular paper and board production line

Valmet’s focus is on supplying papermaking lines with suitable production capacity and sustainable solutions to serve both local and global markets.

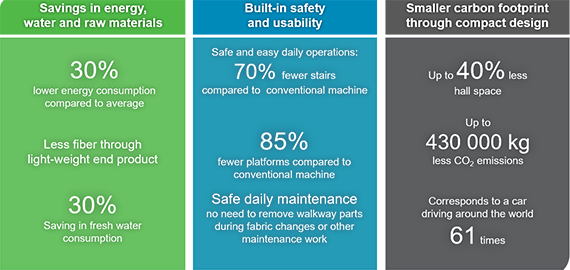

OptiConcept M is a modular paper and board making concept that combines the advantages of standardization with modular tailoring. The modular processes and solutions, set within optimally fixed machine widths, allow the designing of individual lines for customers’ varying needs and targets.

OptiConcept M offers significant savings in energy, water and raw-material usage, built-in safety and usability as well as a smaller carbon footprint through compact design.

Advantage NTT tissue production line for unique flexibility

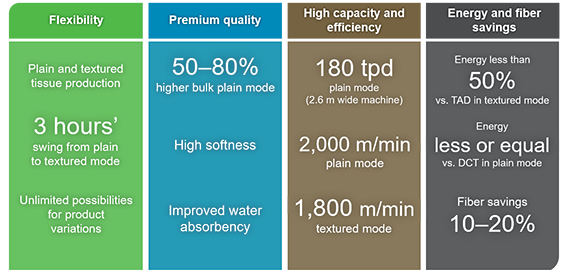

The Advantage NTT Tissue line brings unique flexibility to tissue production, enabling an easy and fast swing between production of plain and textured tissue by changing the belt.

The use of the coarse belt in textured mode creates a structured paper with significantly higher bulk and softness compared to conventional tissue machines, and thus offers an opportunity to produce premium quality tissue.

The specific NTT press allows increased press dryness with maintained paper quality and texture, and the proven NTT technology means trouble-free production with limited downtime. These features, combined with high production speed, enable very high production capacity compared to conventional tissue making.

The combination of belt and NTT press enables the production of premium quality tissue close to the quality of tissue produced by using the ThruAir Drying, TAD, process. The increased bulk makes it possible to produce the same length or size of paper rolls but with reduced use of fiber.