Beyond Circularity: Turning biomaterials and waste into valuable products

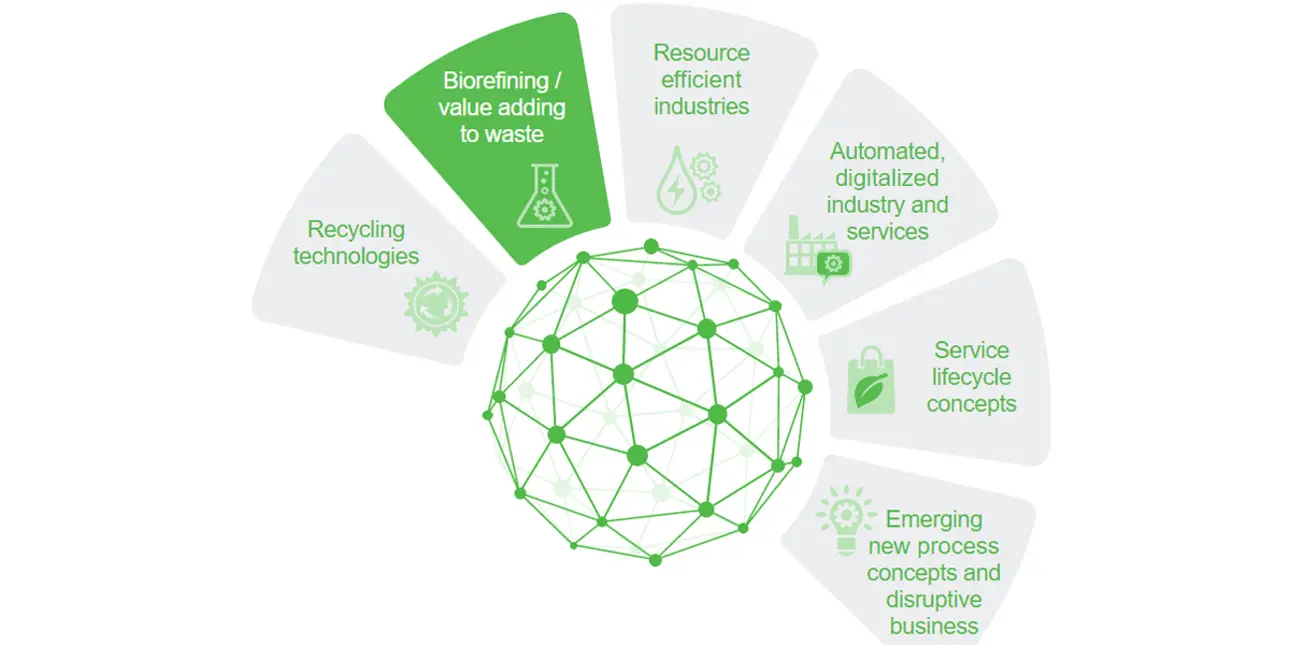

Valmet launched an ambitious R&D program and ecosystem called Beyond Circularity in 2022. It targets the transformation of waste and emissions into valuable resources for sustainable growth and to accelerate the green transition. The program is implemented through seven streams, of which 'Biorefining/value adding to waste' is one.

Why was 'Bio-refining/value-adding to waste' selected as a stream in the Beyond Circularity program?

The target of this stream is to develop technologies for turning biomaterials and waste into valuable products and replacing fossil-based raw materials. This is to support our customers in converting biomass into other products such as biofuels, biochemicals and biomaterials. The basic meaning of bio-refinery is making multiple products from the same biobased feedstock, but we want to do this sustainably.

“Biorefining has been on our customers’ agenda for some time. They’re looking for ways to broaden their product portfolio beyond traditional pulp. At the same time, what has traditionally been seen only as waste is now seen as a new revenue source. At Valmet, we have a long track record in these fields and can support our customers. These topics are also well aligned with our technology vision, and they support our climate program targets,” explains Henrik Wallmo, leader of this stream.

Henrik Wallmo talked about the Biorefining/value adding to waste stream in the Beyond Circularity ecosystem event in September 2023.

What kind of topics does the stream contain?

The stream has five sub-streams:

- Forestry residues and waste: biomass pyrolysis solutions for turning local sustainable feedstocks into global renewable transportation fuels and biochemicals

- Microfibrillated cellulose (MFC): an energy-efficient continuous process for producing microfibrillated cellulose for various applications

- Lignin and ash: novel process solutions for turning ash waste and lignin into new products

- Agro: using agro or non-wood feedstocks to produce pulp and/or other bioproducts

Some of these topics have been under development for some time at Valmet, such as lignin and biomass pyrolysis, and there have been promising results. Some are at the start of their development journey.

Read about some exciting examples:

Pyrolysis – biomass for chemicals and transportation fuels

Pyrolysis is the thermal decomposition of feedstock in the absence of oxygen. The driving force for developing this technology is maximizing the value of resources. Customers seek solutions for producing more valuable products than heat and electricity from biomass, such as chemicals or transportation fuels.

Two pyrolysis-related internal projects are ongoing in the Beyond Circularity program. One focuses on producing chemicals from biomass, and the other on producing transportation fuel.

Valmet’s R&D Center in Tampere is a home for pyrolysis development work. Talented experts have developed and piloted technology there for over a decade.

The pressure to develop more sustainable chemicals is increasing. “Fast pyrolysis technology can be used to produce chemicals from biomass. We’ve already done several pilot tests with small-scale equipment, and the first industrial-scale plant contract was signed in November 2022. A pyrolizer plant is to be delivered to Circa Group’s ReSolute project in France (read the press release). It will produce 1,000 tonnes per year of bio-based solvent called CyreneTM to replace fossil petroleum-based solvents used in various industries,” says Tooran Khazraie, project manager for the Pyrolysis of biomass to chemicals project.

The second pyrolysis project is about utilizing catalytic pyrolysis to produce transportation fuels as an end product of biomass. "This technology is being piloted at Valmet's Energy R&D Center in Tampere, Finland, and initial testing has been very promising. We’re working with collaborators in our network to verify downstream processing and renewable fuel use. Demonstration and commercial-scale cases will follow successful piloting and value stream development,” says Joakim Autio, project manager for the ‘Catalytic pyrolysis of biomass/PICUP' project.

“We’re also working on a co-research project called GreenAro, in which the VTT Technical Research Centre of Finland, Aalto University and Åbo Akademi University are developing new pathways from renewable raw materials to valuable aromatic chemicals with Finnish companies. The project has received funding from Business Finland and the EU,” continues Joakim. Read the article about the project here.

Lignin - a valuable and renewable raw material in a wide range of industries

Lignin is an interesting raw material. It is nature’s second most common macromolecule after cellulose. It is found in all plants and constitutes up to one third of wood composition.

In pilot trials of lignin development for paper and board production, it has been found that lignin can serve as a substitute for starch in surface sizing. Surface sizing is a step in papermaking where a coating is applied to the paper's surface to make it smoother and stronger. Additionally, because lignin is hydrophobic and naturally repels water, it enhances the paper's resistance to water without the need for extra synthetic sizing chemicals.

In the development of next-generation lignin, the target is to develop our ligning extraction process, LignoBoost®, tailoring lignin quality for an improved end-product fit, and to improve the production process at the same time. There is a clear focus on accelerating the speed with which we are meeting the growing future lignin demand. Read more about Valmet’s lignin extraction technology.

New technology for surface application of Micro-fibrillated cellulose

Paper and board have many advantages as materials for packaging; they are lightweight, durable, bio-based, and easily recyclable. However, paper and board lack the necessary barrier properties for food packaging, and therefore, an additional barrier layer is often added. Today, this layer is typically made from polymers like polyethylene terephthalate, or polyethylene, or aluminum. There are efforts to replace these materials with bio-based, biodegradable films to reduce environmental impact.

Micro-fibrillated cellulose (MFC) offers an excellent bio-based, biodegradable grease and oxygen barrier for packaging. However, it is quite different from the traditional barrier layers and requires new technology for applying it on paper.

Valmet has developed technology to apply MFC and other additives to the wet end of the paper machine using a specially designed Applicator system. The Valmet Wet End Applicator can easily be retrofitted to existing machines. It can provide uniform coverage and excellent CD distribution to improve sheet surface smoothness and significantly improve barrier properties. It can provide papermakers with a new tool for developing new grades of paper and green solutions for their customers.

Can you help us to transform waste and emissions into valuable resources for sustainable growth? Join our ecosystem!

"We are continuously welcoming new partners to our ecosystem. If you are interested in ecosystem partnering, please see more information from our Beyond Circularity page," says Virpi Puhakka,Director, Ecosystem at Valmet.

If a joint project is accepted for the Beyond Circularity ecosystem (with Valmet approval), Finnish partners may submit a partnership funding application to Business Finland. Business Finland offers partnership funding for research, development and innovation projects under the ecosystem themes of the Beyond Circularity program.