Valmet enables circular economy

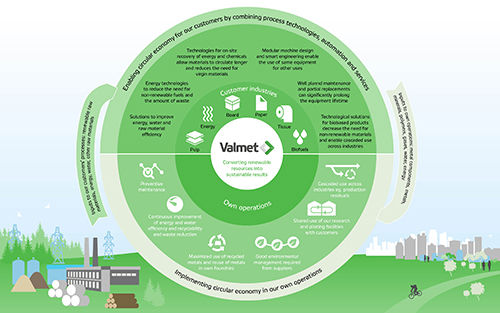

In circular economy, products, components and materials stay in a continuous cycle instead of being thrown away. The key idea is to take as little new materials into use as possible, use existing material flows as long as possible and to minimize the amount of waste. This can be achieved by reducing the initial need for raw materials, by circulating the materials longer in the process, by recycling the used materials, and by prolonging the lifetime of production equipment with well-planned maintenance. This very idea is built into Valmet’s solutions for customers.

Valmet promotes and enables circular economy in its customers’ as well as in its own operations. Click to view the figure larger.

Valmet has a strong role in circular economy

Demand for a more resource-efficient and clean world is driving the need for more sustainable solutions. Valmet has a strong role in the circular economy as an enabler by offering customers technology and services for converting renewable resources into sustainable products.

Valmet enables circular economy through many ways by combining process technologies, automation and services and is constantly developing new technologies and services to support the circular economy. Valmet works with customers to utilize its research and pilot facilities to develop solutions that meet the customers’ needs. Valmet has identified six key areas where Valmet’s solutions help our customers to achieve more sustainable business.

Valmet’s solutions for circular economy

1. Improvement and optimization of resource efficiency

Resource efficiency can be improved through technology, automation and maintenance. Significant savings in energy, water and raw materials can be achieved through technologies such as Valmet’s OptiConcept M paper and board machines, as well as Advantage DCT and Advantage NTT tissue machines. Valmet’s Industrial internet solutions enable data analytics to detect production inefficiencies and optimizes material use. Performance agreements provide a comprehensive approach to improve mill wide production efficiency.

2. Flexible energy production

Valmet’s technologies for flexible energy production reduce the need for non-renewable fuels and the amount of waste. Waste-to-energy solutions by fluidized bed boiler and gasification technologies enable efficient energy recovery. Multi-fuel boilers enhance fuel flexibility and can operate on fuel mixtures ranging from 100% coal to 100% biomass. Fluidized bed boilers enable wider use of fuel sources, which can utilize fuels with varying energy value and moisture content.

3. Chemical and energy recovery

On-site recovery of energy and chemicals allows materials to circulate longer and reduces the need for virgin materials. Recovery island enables efficient recovery of chemicals and energy in a pulp mill. Condensate water recycling and paper pigments recovery are examples of internal recovery and recycling solutions.

4. Design enabling reuse and conversion

Modular design and smart engineering enable the use of same equipment for other uses. Paper machines can be converted to produce board or other paper grades and machines can be dissembled and reassembled in another location. Flexible design enables changes based on market needs. Modular I/O-cards (input/output cards) enable system updates without the need to update the core system.

5. Maintenance and modernization of production technology

Well planned maintenance and partial replacements can prolong equipment lifetime. Preventive maintenance can be planned by utilizing big data analytics e.g. in roll maintenance. Refiner segments, rolls and certain wear parts are refurbished and can be reused. Individual process parts or complete mills and power plants can be modernized to extend the life time. Boilers can be modified to use another fuel e.g. from coal to biomass.

6. New bio-based products

Solutions for new bio-based products decrease the need for non-renewable materials. LignoBoost technology makes it possible to extract lignin from pulping process side stream, and lignin can be used as raw material for bio-based materials and chemicals. Technologies for bioethanol, biocoal and bio-oil production help to replace non-renewable fuels and materials.