Winder drum covers for board and paper making

Resilient roll covers in winding for improved runnability

Valmet’s soft roll covers for winding applications provide good wear resistance and durability for high speed winding, resulting in long running times and high production levels. The hard thermal coatings for winder drums are even applicable on-site, with no need to remove the drum from the winder.

Long running times

Enabling tighter winding, removing air and preventing wrinkles

Hard coating solution ideal for on-site coating

Requirements for efficient winding

The winding process presents tough requirements for roll covers in wear and marking resistance, strength and traction grip. With its long history of producing hard thermal coatings and solid expertise in soft polyurethane covers, Valmet offers a suitable roll cover solution for all winding purposes.

Tackle dishing and quality problems

The flexible Valmet Winder Drum Cover is designed for winder drums making heavy customer rolls. Large diameter customer rolls in winders can generate crepe wrinkles or poor roll quality due to slippage with low frictional grades. Such problems can be prevented using a flexible cover on the winding drum. With the compliant and gentle Valmet Winder Drum Cover polyurethane cover it is possible to generate tighter winding onto the rolls removing air and preventing wrinkles and dishing at reduced nip stresses, without risk of marking the paper with the grooves.

The flexible Valmet Winder Drum Cover allows high nip pressure and prevents dishing

Protecting hard coating for winder and reel drums

Valmet Reel Drum Cover TM is a long-lasting traction coating with a surface quality optimized for each paper grade. It protects the drum from wear while maintaining a suitable surface roughness. Combined with a special groove design it gives the needed torque. The cover is ideal for on-site coating, often coated during planned shutdowns.

Find optimal roll covers for every board and paper process

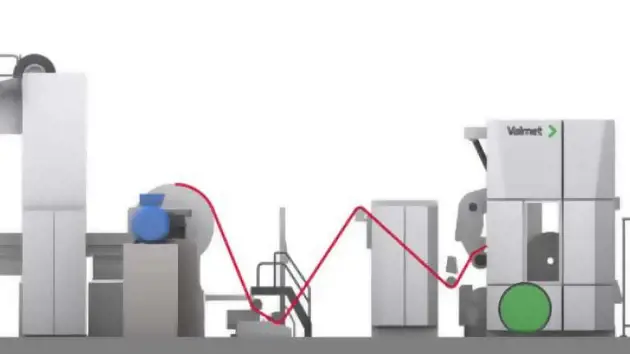

Explore our roll cover products targeted for winding from interactive demo. By exploring this roll cover application tool you can easily see different cover options for every board and paper making process.

Start exploringQuestions about roll covers?

Answer a few questions and our roll experts will contact you shortly.

Contact usReferences and articles

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}