Forming roll covers for board and paper

Roll covers to protect against wear and corrosion

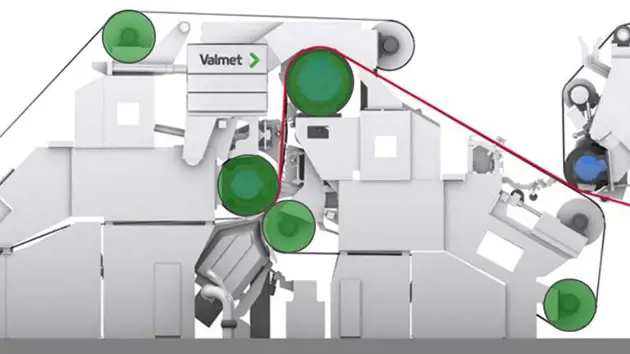

Valmet has a wide range of protective lead and drive roll covers for the forming section rolls of your board or paper machine. We have developed unsurpassed polymeric covers and hard coatings for different needs.

Long service life due to good wear and chemical resistance

Excellent corrosion resistance

Easy doctoring

Protection in harsh, abrasive and wet environment

The universal task for roll covers in the forming section is to maintain roll dimensions such as the roll diameter profile in CD, so that wires can be rotated and guided smoothly and gently in the rolls without slipping or other problems. Valmet lead roll covers protect rolls in harsh, abrasive and wet environment from wear and corrosion.

Valmet Lead Roll Covers

Valmet Drive Roll Covers

Roll cover requirements for tube and drive rolls

Roll cover materials such as ceramic coatings with extremely high wear and corrosion resistance are essential for the forming section. Besides steel tube rolls, stainless steel suction rolls and carbon fiber tube rolls can be coated with Valmet’s high-performance covers. Wire drive rolls need proper traction, and positions requiring the highest traction from the roll surface will need Valmet drive roll covers, which are durable soft rubber or polyurethane covers. Along with top-of-the-line roll covers, Valmet can support papermakers with other forming section services, such as optimal doctoring solutions.

Questions about roll covers?

Answer a few questions and our roll experts will contact you shortly.

Contact us

Explore our forming roll covers and coatings from interactive demo

By exploring this roll cover application tool you can easily see different cover options for every board and paper making process.

Start exploringCeramic coatings for lead rolls

As a pioneer in ceramic coatings, Valmet has gathered its decades of experience to introduce a new generation of ceramic roll covers for lead rolls. In containerboard machines, these hard and extremely durable coatings ensure longer run time and better reliability. Read more about new ceramic coatings.

We prefer a situation in which the lead rolls can be left in the machine for several years without having to repair or even think about them.”

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}