Tail threading for board and paper making

Safety and efficiency through total tail control

A reliable tail threading process decreases tail threading times, minimizes waste and improves safety. This means an investment in your process is an investment that pays for itself. Whether you need improvements in paper or board machines, we have an advanced tail threading solution that clearly enhances your production efficiency. Our comprehensive range of tail threading services, from preventive maintenance to tail threading study secures optimal operation of your equipment and reduces threading times.

Enhance the efficiency of the production line

Improving operator safety

Minimizes waste

Ropeless tail threading solutions for board and paper machines

Compared to conventional carrier rope systems, the ropeless and automated tail threading solutions achieve significantly shorter tail threading times. It also improves operator safety: no accidents due to ropes.

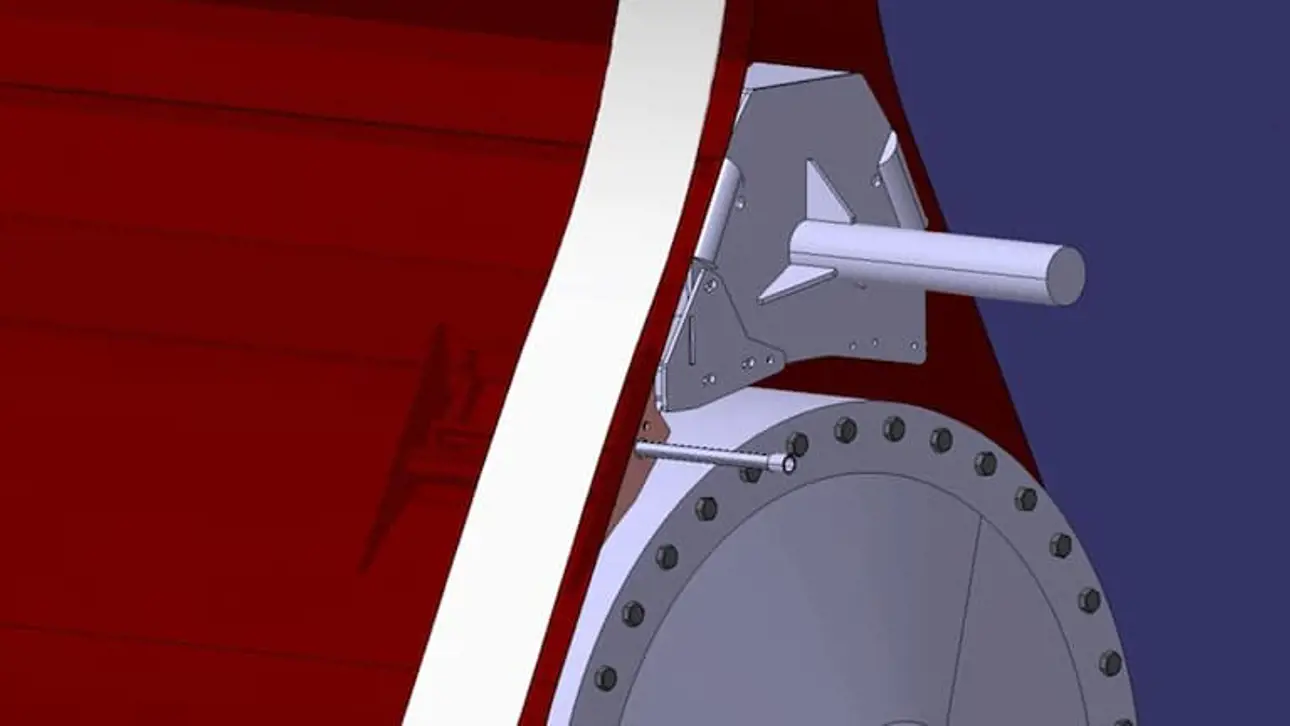

Tail cutting solutions for board and paper machines

Our tail cutting and widening solutions for forming, press and dryer

sections provide better controllability and uniform tail quality for the tail

threading process. Tail cutting is performed with water jets or by a mechanical cutter such as TailCutter, a reliable solution for heavy paper, board and pulp grades.

Temperature monitoring solution for board and paper machines

Valmet Sheet Temperature Detector is a non-contacting temperature monitoring system. It measures either sheet or dryer surface temperature depending on case-specific circumstances and the operating status of the dryer section. It will improved tail threading and runnability.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usReferences and articles

Start the discussion about tail threading for board and paper making

Tail threading is a crucial step in the operation of paper and board machines. It involves guiding the paper tail through the press section, dryer section, and reel section after a break or start up. An important part of the process is the threading belt and the fabric. The threading belt helps ensure the paper tail is smoothly and efficiently transferred from one section to another. A reliable tail threading process decreases tail threading times, minimizes waste and improves safety. When the process is performed efficiently, it minimizes downtime and reduces the risk of web breaks, leading to higher production efficiency.

At Valmet, we understand the significance of efficient and reliable tail threading solutions in the paper and board making industry. Valmet's tail threading offering, including farbic and threading belt, is built on years of experience and expertise in the paper and board industry. Our commitment to continuous innovation ensures that our customers have access to the latest advancements in tail threading technology. Our comprehensive range of tail threading services secures optimal operation of your equipment and reduces threading times. Additionally, our tail cutting and widening solutions provide better controllability and uniform tail quality for the tail threading process. We have tail cutting machine suitable for all printing, board and pulp grades.

Our dedication and expertise enable us to be your trusted partner in tail threading. Contact us today to learn more about our comprehensive tail threading solutions and how we can help you achieve your targets.