Automatic production, consumption and efficiency reporting

Valmet DNA Plant Operation Monitoring

Valmet DNA Plant Operation Monitoring provides automatic plant production, consumption and efficiency reports. The application brings real-time figures to internal users wherever they are at the site. Adjustments and corrective actions can be made as soon as necessary, improving overall plant efficiency, performance and profitability. In addition, having all relevant production and consumption data in one place facilitates invoicing, purchasing and budgeting.

Reduced time spent on data gathering and reporting

Consolidated crucial production, consumption and performance figures on a laptop screen

Improved process efficiency with easy-to-use trending tools

Reduced production costs and improved competitiveness in the energy market

Automated data gathering and reporting

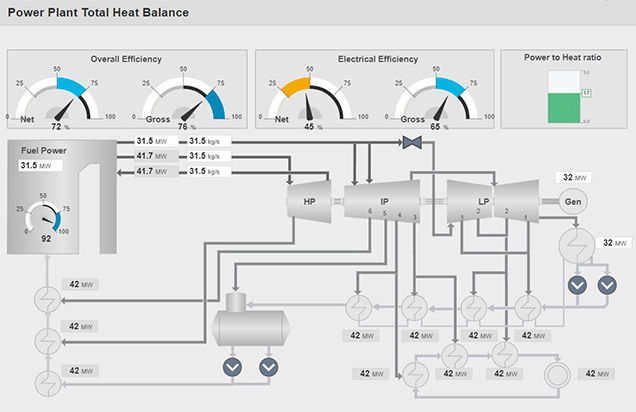

The Valmet DNA Plant Operation Monitoring application frees up valuable resources from the time-consuming data gathering process. The solution automatically calculates, stores and displays all relevant production and consumption data and provides power plant personnel with comprehensive reports. In addition to reporting output and fuel consumption figures, it monitors the power plant’s overall heat balance, water/steam balances and other parameters.

The tool’s user interface produces a combination of customized reports and displays. These visualize the operation and performance of the power plant and report the cumulative production and consumption data. The figures can be used in a variety of ways, for example, reviewed at regular morning meetings to help plan the tasks of the day.

Furthermore, the availability of history data enables long-term analysis of plant efficiency figures. This helps reveal weak points in the production and further improve process efficiency.

Seamless integration with other automation applications

Valmet DNA Plant Operation Monitoring links seamlessly to the overall automation applications, guaranteeing efficient collaboration between plant management and plant control.

It can be used as a standardized application at all types of power plants, including fluidized bed combustion, condensing power, combined heat and power, combined-cycle power and energy-from-waste plants.

Would you like to find out more about our performance solutions?

Please let us know more about your needs – and our experts will contact you shortly.

Contact us