Reduced maintenance costs with real-time boiler component wear monitoring

Valmet DNA Boiler Life Monitoring

The Valmet DNA Boiler Life Monitoring application calculates, stores and displays all factors indicating operating stresses and wear of critical coal boiler components. By providing estimations of component service life, the solution facilitates decision-making, optimizes maintenance planning and reduces the risk of unscheduled shutdowns.

Optimized plant operations and maintenance planning

Reduced costs associated with boiler component maintenance and unscheduled shutdowns

Increased output with shorter start-up times and quicker load changes

Instant alerts when restricted limits are exceeded

Stable plant operation with reduced thermal stress

Valmet DNA Boiler Life Monitoring helps estimate effects caused by startups and load changes and adjusts accordingly. To reduce thermal stress and fatigue damage that is especially common in coal-fired power plant boilers, the solution may also be used to optimize the steam generator operations and spot any superheater tube overheating. This assists in extending the lifetime of components and reduces the risk of unscheduled shutdowns.

Knowing exactly where maintenance is required

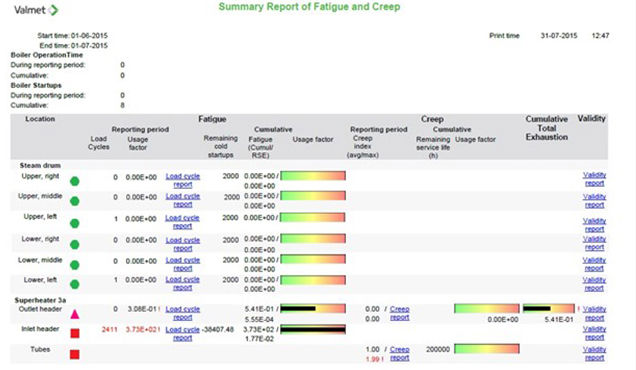

The graphical interface of Valmet DNA Boiler Life Monitoring includes both displays and reports with calculated variables for drum, headers and superheater tubes. All calculations are built in accordance with appropriate steam boiler standards.

Comprehensive analysis of boiler component wear can be used to reduce inspection times and any maintenance work required. The storing of history values enables long-term reporting and trending, thereby helping in the comparison of different modes of operation – and optimizing operations accordingly.

The application is seamlessly linked to the overall automation applications, guaranteeing efficient collaboration between plant management and plant control.

Would you like to find out more about our performance solutions?

Please let us know more about your needs – and our experts will contact you shortly.

Read More