Improved power plant economy

Valmet DNA Pumps and Fans Performance Monitoring

The Valmet DNA Pumps and Fans Performance Monitoring application provides power plant personnel with valuable information about the performance, condition and operating efficiency of their pumps and fans – both in real time and retrospectively. Continuously monitoring the operation of pumps and fans enables the detection of failures before they become severe. This helps significantly reduce maintenance costs and power plant electricity consumption.

Reduced power plant electricity consumption and maintenance needs

Detection and analysis of potential or existing operational issues for pumps and fans

Improved maintenance planning with long-term monitoring of component deterioration

Minimized downtime with a proactive approach to failure prevention

Stable pumps and fans provide continuous efficiency

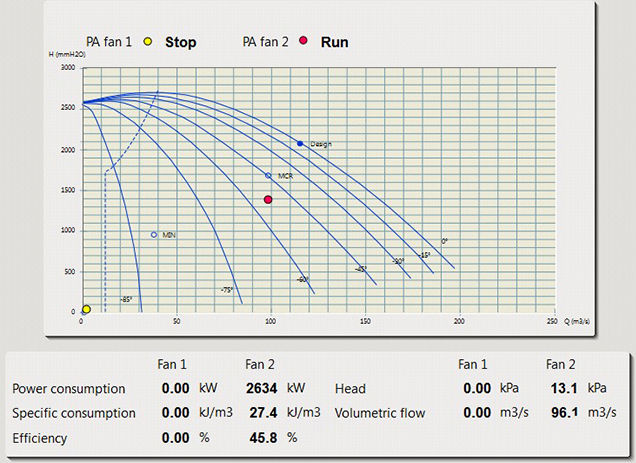

The Valmet DNA Pumps and Fans Performance Monitoring application continuously calculates, displays and stores the main operating parameters of power plant pumps and fans. Calculations include the most important performance parameters, such as head or pressure difference, specific consumption and efficiency.

Real-time comparison of actual operating points with reference values provides accurate information on the condition of pumps and fans, if OEM data is available.

The application also helps power plant maintenance and operating personnel detect potential problems in the operation of pumps and fans and analyze those that have occurred. This prevents failures proactively – before they cause unpredicted shutdowns.

Additionally, extensive storage of history data enables long-term monitoring of gradual component deterioration and mechanical failures, for significantly improved maintenance planning.

Open and flexible system structure

Valmet DNA Pumps and Fans Performance Monitoring is a standardized application customized to meet the specific needs of each power plant process. The solution’s openness and flexibility make it suitable for all common pump and fan models. With the tool’s customized user interface, all essential performance data is clearly shown in easy-to-use reports and displays. The application is seamlessly linked to the overall automation applications, guaranteeing efficient collaboration between plant management and plant control.

Would you like to find out more about our performance solutions?

Please let us know more about your needs – and our experts will contact you shortly.

Contact us