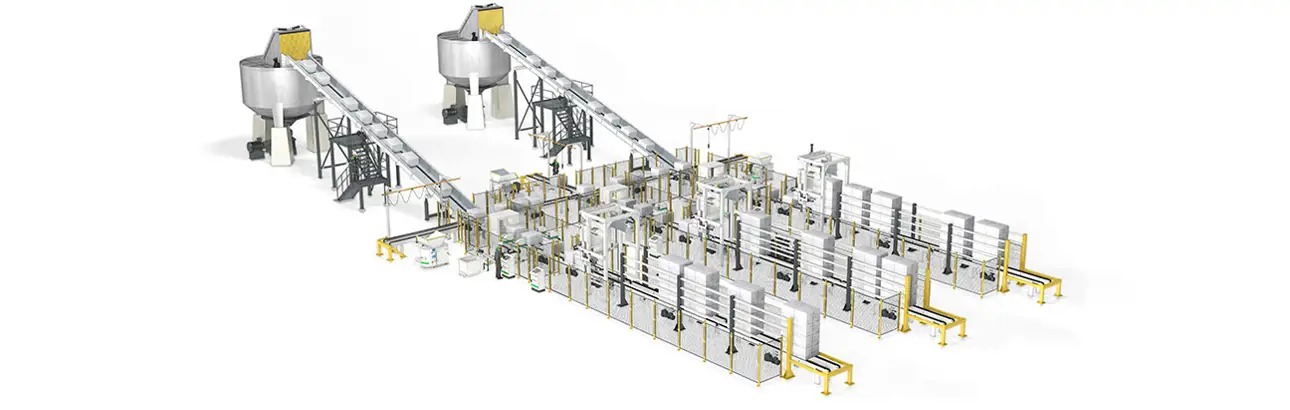

Valmet Pulper Feed System and dewiring equipment

A Valmet solution for pulp receiving lines offers a best-in-class combination of hardware and software for efficient automatic dewiring, destacking and recipe handling in the delivery of baled pulp to continuous or batch pulpers. We provide an optimized configuration of highly reliable machines, sophisticated control system and heavy-duty conveyors to match each customer’s specific line requirements. Our complete automatic pulper feed system for baled pulp enhances efficiency, safety and flow control.

Let's stay safe

Valmet’s fully automated pulper feed system comes with a wide range of benefits. Not only does it cut costs, it also offers higher productivity and efficiency and improves staff safety by eliminating the risks associated with manual dewiring routines. The main machines, used for dewiring and destacking, safely converts cut wire into compact recyclable coils. The installation is divided into safety zones. If anyone enters a safety zone, all power sources are interrupted which ensures highest possible safety level for all employees. To really secure the area, an abound of safety devices can be applied around the line. Doors are installed for easy access to operating and maintenance positions. Individual sections of the fence can easily be dismounted with a special tool if needed. Light beam sensors or scanners can be used to improve accessibility where a fence is considered to be too restricting. The safety system is always adapted to local safety laws and regulations before delivery. We have used our life experience to create a safe working environment for you.

Let's be smart

Each individual bale, bale set and bale unit is tracked throughout the line. Using absolute bale position tracking to ensure exceptionally reliable key data on production and quality, the system enhances efficiency, logistics and quality management.

Recipe handling to ensure the required pulp quality reaches the pulper can be a complex and challenging process for operators of manual recipe handling stations. Valmet has developed an advanced recipe handling software to automatically track, sort and collect bales. The software automatically calculates the mix of bales needed to ensure the required quality and guides the movement of bales to keep the production flow constant. The recipe handling software is always tailored in close cooperation with the customer to fit specific needs. Connected to our industrial internet services you will have real time access to monitored data, and on-demand expert support, whenever you need it. It has never been easier to optimize your operations.

Let's ensure your efficiency

Our machines are delivered as ready-to-use units designed for fast installation and start up. Efficient everyday operation is ensured by the superior control system, featuring PLC control equipment, which is operated and monitored via a touch-screen with an easy-to-use graphic interface.

Our automatic pulper feed system efficiently removes wire from bale stacks and single bales. Conveyor systems are connecting the machines for recipe handling, storing, transportation and manual dewiring.

We have the fastest dewiring solution available for single bales, with rates of up to 140 bales/h when cutting the commonly used 2+2 wire configuration.

Automatic, semi-automatic or manual systems, we will adapt to your special need and supply the most suitable tools to make your operation as efficient as possible.