Outstanding performance and retained bulk with belt-bed winding

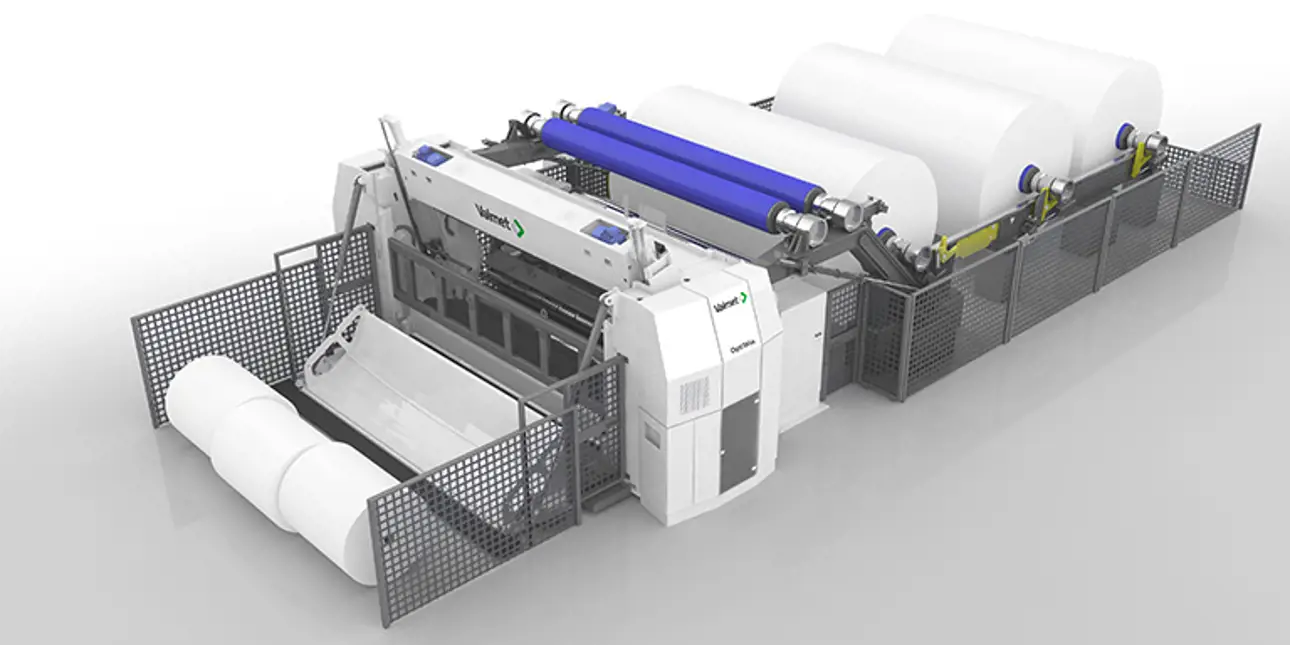

OptiWin Belt belt-bed winder

OptiWin Belt features the belt-bed winding method, which is renowned for its outstanding performance and unrivaled roll quality. Belt supported winding is advanced two-drum winding for demanding grades, such as coated board, LWC and release grades.

High capacity

Compact size

Quick installation

Controlled nip load

Unique winding method

With OptiWin Belt, rolls are wound on a driven belt-bed and a rear drum. As the roll diameter increases most of the roll weight is transferred to the belt-bed. Proper nip load distribution between the belt-bed and rear drum is controlled by maintaining an appropriate winding angle and belt tension. This control of excessive nip load retains bulk and prevents roll defects such as crepe wrinkles, uneven gloss, and mottling. Controlled nip load is highly important with high-density grades.

Winder installation and start-up take only a minimum of time, since the wind-up frame is one complete unit and belt-bed tests are carried out during workshop assembly.

OptiWin Belt offers the broadest operating range of winding force (the peripheral force exerted by the belt-bed to the set), which is used as the primary tool to control the roll structure. Winding force together with controlled nip loads allow accurate roll hardness control and ensures superior roll quality.

Want to talk to our winders and roll handling experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsAutomation to your needs

OptiWin Belt’s automation level can be tailored according to each mill’s needs. The winder can also be equipped with Continuous Winding for fully automated winding performance that allow one-man winder operation.

We invite you to carry out your winding trials at Paper Technology Center. All winding technologies can be tried out with your own paper or board.

Valmet´s famous WinDrum Pro, WinDrum, WinDrum Compact, WinBelt and pulp winders are now available under the renewed OptiWin winder family.

Planning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookInterested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsLearn more about the services and automation solutions for winders

Explore our latest board and paper press releases

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China