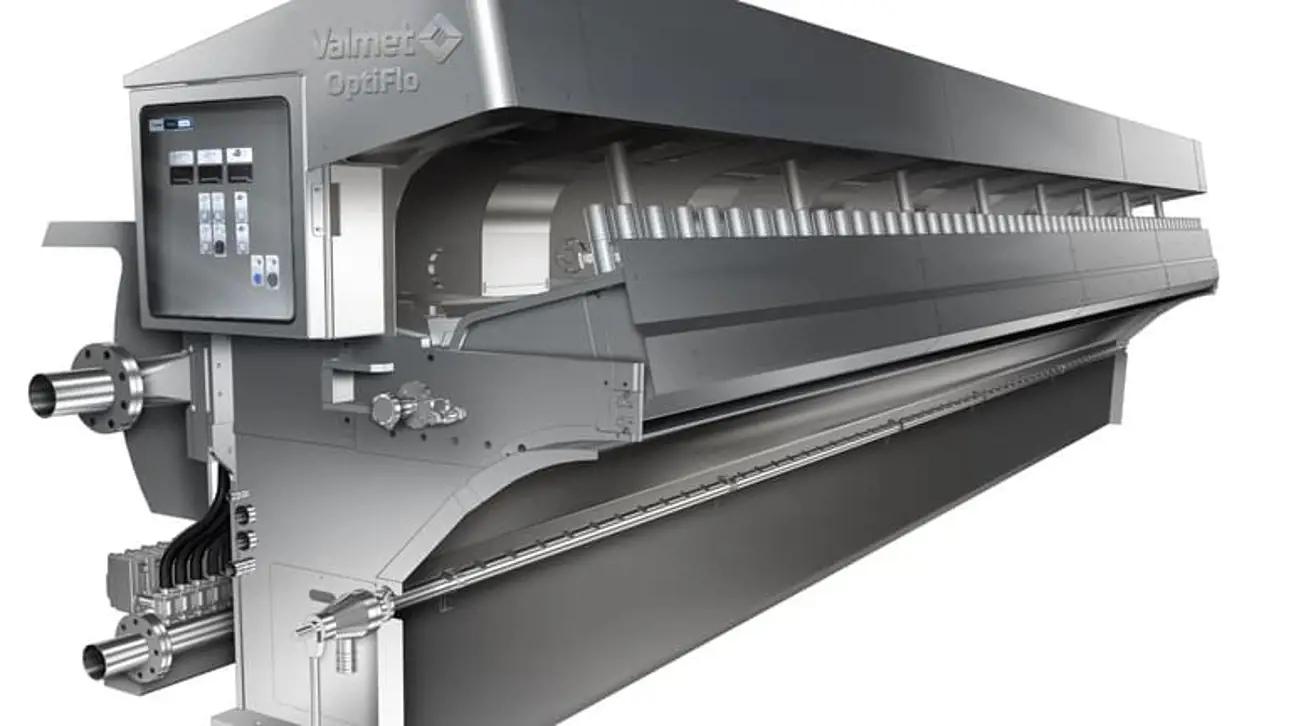

Headbox improvements for board and paper making

Customized solutions that will improve headbox related sheet quality and headbox performance

We provide customized solutions for improving headbox-related sheet quality and headbox performance. With improvements in headbox area you can reduce your cost per tonne produced through savings in raw materials, energy and/or maintenance costs.

Reduced energy costs

Raw material savings

Reduced maintenance cost

Savings in raw materials and maintenance cost with headbox condition management

Consistently high-level stable production and headbox performance can be maintained through preventive and predictive maintenance. Headbox condition management solutions are targeted at keeping your headbox in good condition and facilitating cost-effective maintenance practices. This will result in improved production efficiency and savings in raw materials and maintenance costs.

Stable quality and improved production efficiency with headbox profile management

Better and more uniform dry weight profiles yield better moisture profiles and provide opportunities for optimizing the drying process, which often produces significant energy savings. Headbox profile management solutions are designed for better and more stable quality, which improves production efficiency and thereby provides cost savings in the form of furnish optimization.

Energy savings with headbox performance upgrade

Headbox performance upgrade solutions help you with improved profile control methods for dry weight or orientation profiles, faster startups, better understanding of process variables, and improved headbox cleanliness and runnability. Performance upgrade solutions provide energy savings through fewer breaks, materials savings through furnish optimization, and more uniform profiles for better paper quality.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usReferences and articles

Related pages