Improving paper strenght with hard nip sizing

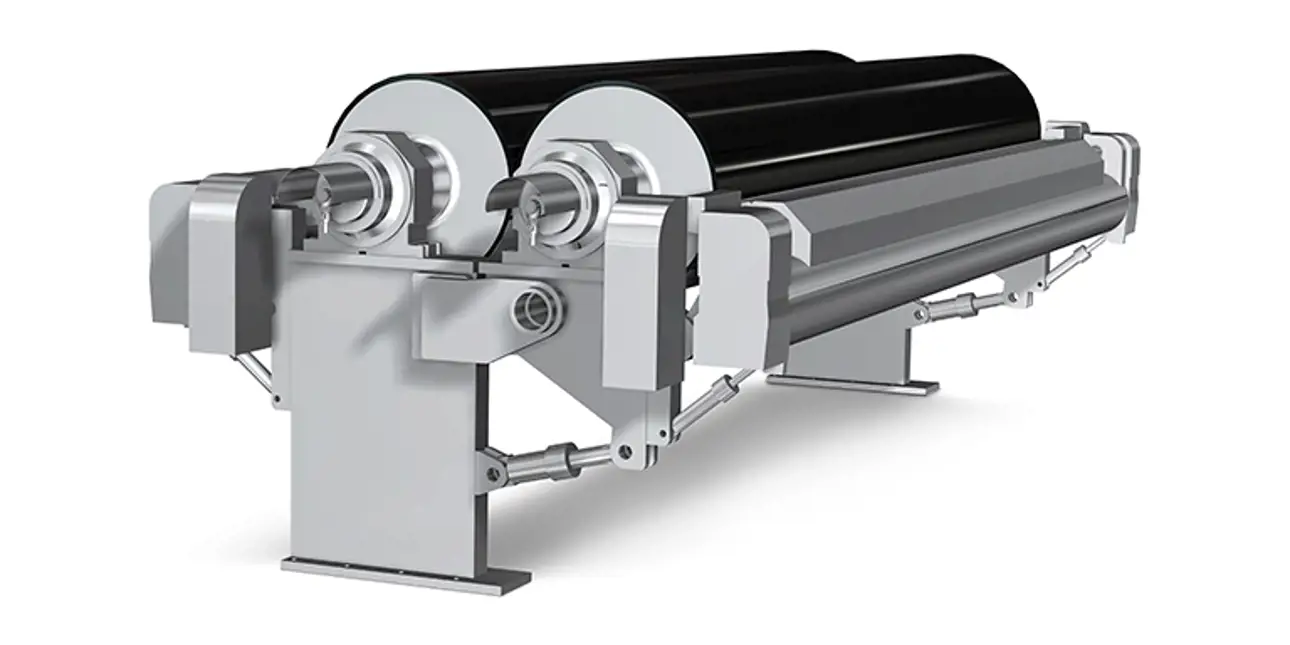

OptiSizer Hard

Strength is the main target when applying starch on board or paper. Starch located in fiber bonds has the biggest strengthening effect. Total strength of paper sheet can be improved the most by increasing the bond strength of the paper fiber network. OptiSizer Hard is a completely new size application method, which uses higher nip loads to improve sheet strength properties by taking advantage of better starch penetration and decreasing fiber to fiber distance.

Lower energy costs and raw material savings

Good strength and quality properties

High operational efficiency

Lower maintenance costs

Sheet wetting = good penetration ≠ good strength

More starch doesn’t directly mean more strength. Most of the starch is in a way ineffective when positioned in the pores of the fibers or the void volume in the paper sheet. By applying more starch, you might just end up wetting the sheet without any strength improvement. The key is to increase nip load.

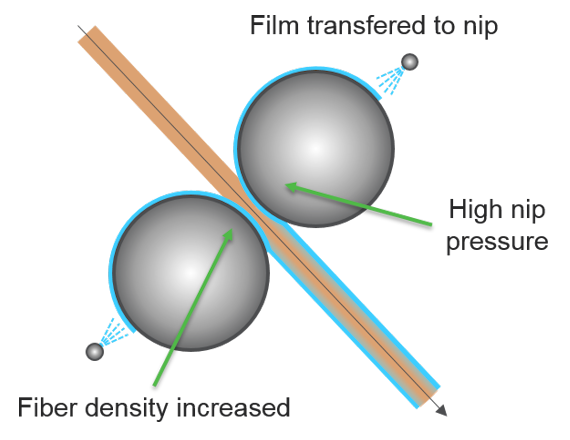

Principle of hard nip sizing

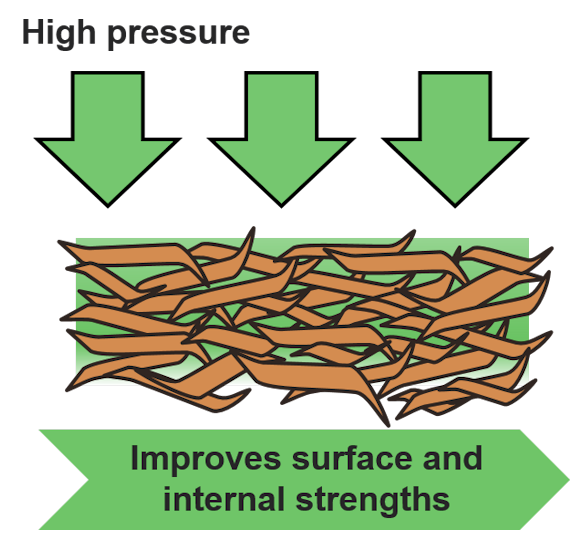

High pressure increases both surface and internal strength by increasing the bond strength of the fiber network

Good strength and quality properties

With containerboards, it is important to have good burst resistance properties, which gives the boxes their required protective properties. For good burst results, high surface and internal strengths are a must. As said earlier, total strength is improved by increasing the bond strength of the fiber network – better starch penetration needed.

With OptiSizer Hard, starch is first sprayed on the rolls which transfer the starch into the nip where it is further transferred into paper web. The roll nip with higher nip pressure increases the density of fibers.

This way starch enters fiber junction points, not only the void volume. When fiber to fiber distance is relatively small, the porous volume is small and the pressure for liquid diffusion is large. There will be more starch in fiber junction points and better starch penetration. All this leads into better strength properties with OptiSizer Hard.

Lower maintenance cost and good runnability

The application method and hard nip rolls of OptiSizer Hard are quite different from the conventional sizers. This delivers quite a few nice benefits such as lower life cycle costs and better runnability.

Life cycle costs are lower due to the fact there are no consumables such as metering rods, rod beds nor sealing blades. Because of hard cover of nip rolls, the grinding interval is longer compared to film sizing. There is no rod scraping the surface and wear resistance is good. Unlike with conventional film sizing, there is a possibility for doctoring leading to good roll cleanliness and no wrap-ups in breaks.

The deflection compensated rolls with hard coves give high loading capacity and good profile features. Therefore, there are no wrinkling nor tension problems with the sizer resulting good runnability.

Lower energy and raw material costs

High solids in starch bring savings in drying energy and release drying capacity. Additionally, less starch is needed for the same sheet strength. The starch amount is easily controllable. Accurate control is achieved by adjusting feeding pressure. Fast response to changes in solid content is possible due to low volume system.

By applying more starch, you might just end up wetting the sheet without any strength improvement and incereasing the need of drying - and use more energy. With OptiSizer Hard you save energy and money.

Better results in corrugating

When making corrugating medium, glue must be well-absorbed into both fluting and liner layers for a strong bond. Even with high size amounts, the sheet structure maintains its permeability because of higher nip load. This also gives a better fluting and liner layer joining in converting. Sheet permeability is better maintained with high size amounts.

Read also more about the latest development in sizing: read more.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreLearn more about the services and automation solutions for sizing

Explore our latest board and paper press releases

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China