Innovative dewatering with forming fabric compression

Sleeve roll technology

The journey to innovate board and paper machine technology has led to the breakthrough known as Sleeve roll technology. This innovative technology redefines dewatering by harnessing the power of compression already in the forming section, reducing the need for energy-intensive vacuum methods that conventional forming technologies rely on. Uncover the benefits, applications, and transformative impact of the Sleeve roll technology on the board manufacturing landscape.

Competitive investment costs compared to conventional solutions

Significant energy savings compared to conventional technologies

Maintaining strength while using lower-quality raw material

For multiple forming concepts

Sleeve roll technology: today's innovation, tomorrow's norm

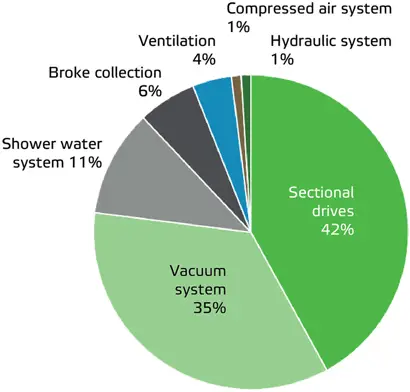

The forming section is the biggest user of vacuum energy on paper and board machine lines. Until now, forming section drainage has relied on gravitation and dragging vacuum elements set along the forming fabric’s journey. Sleeve roll technology does not require vacuum energy, and therefore it saves energy in both the vacuum system and drives of the forming section. Data from production machines shows that the dewatering of the forming section with Sleeve roll technology is effective and that is clearly visible in the power consumption of drives and vacuum pressure. Dewatering on a board gap former has been up to 160 l/s, depending on the former speed and the web’s ingoing consistency in the Sleeve roll. A normal plain roll does not remove any water in this position. This results in 23% energy consumption savings in forming section drives, when there are no vacuums before the Sleeve roll.

Forming section energy usage

From concept to reality

Sleeve roll technology has quickly transitioned from concept to reality. The pilot-tested applications are now setting the new standard in production machines for gap, hybrid and multifoudrinier formers. This novel forming technology has found its home in Valmet's rebuilds and new board machine lines, by showcasing energy efficient dewatering and improved paper quality.

By integrating Sleeve roll into your processes, you're not just adopting an innovation – you're embracing the sustainable future of board manufacturing.

Production capacity increase

18%

In hybrid former rebuild

Energy savings

23%

In new gap former

Improvement on internal bonding

10-13%

In hybrid former rebuild

Reduction in steam consumption

4-8%

In multi former rebuild, with Sleeve roll in combining position

Want to talk to our experts?

If you wish to get further information on the Sleeve roll technology, like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsEmbrace efficiency, elevate quality – Choose Sleeve roll technology

Sleeve roll technology introduces a paradigm shift in forming section dewatering efficiency. By embracing compression rather than traditional vacuum-based methods, this innovation offers a range of compelling benefits:

- Energy efficiency: Say goodbye to excessive energy consumption. Sleeve roll's prepressing mechanism significantly reduces forming section drive power requirements, leading to substantial energy savings of up to 23%, which have been achieved in a new gap former installation with Sleeve roll technology. On a multi former rebuild, with Sleeve roll in combining position, 4 to 8% reduction in steam consumption was achieved, even when speed increased. Lower CO2 emissions become a reality, contributing to your sustainability goals. A sustainable choice for both your operations and the environment.

- Enhanced quality: Elevate your product quality to new heights. 15 to 20% formation improvement and 10 to 13 % improvement on internal bonding were seen on hybrid former rebuild with Sleeve roll technology. In a multi former rebuild, with Sleeve roll in combining position, several quality improvements were seen: 5% on compression CD, 8% on compression MD, 10% both on bursting strength and internal bond. In general the outgoing dryness from forming section on all the delivered production machines with Sleeve roll, is constantly at high level from 25 to 27%. Improved board quality leads to heightened customer satisfaction and market competitiveness.

- Improved performance: Embrace higher production capacities. Sleeve roll technology optimizes dewatering processes, minimizing downtime, and maximizing throughput. In a hybrid former rebuild time efficiency was improved as number of breaks and grade change time were decresed after the rebuild. Also, winder runnability was improved due to more stable dryness in MD and CD direction. In total, a 18% production incease was seen after the rebuild with Sleeve roll technology. On multi former rebuild, with Sleeve roll in combining position, 8% improvement on productivity was achieved and sheet breaks reduced signifigantly after the rebuild, by 62%.

Elevate your board manufacturing process with Sleeve roll technology. Join the league of forward-thinking manufacturers who have harnessed its benefits. Make your mark on the industry while reducing energy consumption and enhancing product quality. Sleeve roll technology – where innovation meets results.

Sleeve roll technology in different forming section concepts

Sleeve roll technology is already an established technology in hybrid, board gap and multi-fourdrinier concepts on production scale. We have tested Sleeve roll technology on many concepts and positions in pilot trials at our Paper Technology Center successfully. The position of the Sleeve roll shoe can be in almost any compass direction making this technology suitable for multiple forming section concepts.

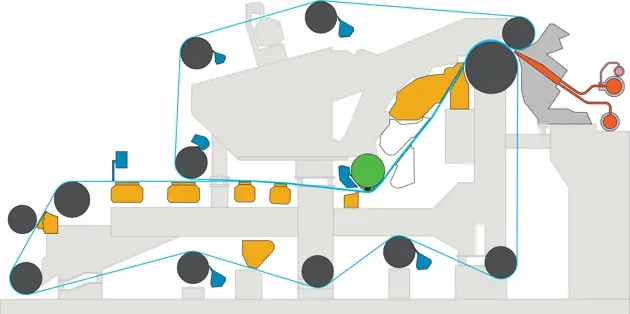

Sleeve roll in hybrid former

This production machine produces recycled fluting grades in basis weight range from 90 to 300 g/m², with design speed of 1,300 m/min. In this project a traditional fourdrinier forming section was rebuilt with top former loop, forming roll and Sleeve roll. The rebuild target was to increase production and improve end-product quality and both of these targets were achieved.

Sleeve roll in board gap former

This new high capacity containerboard machine produces recycled fluting and liner grades in basis weight range from 60 to 110 g/m², with design speed of 2,000 m/min. Energy efficiency was one of the main reasons for choosing Sleeve roll technology to this machine line. 23% energy savings in forming section drive power have been achieved when utilizing the full potential of the Sleeve roll.

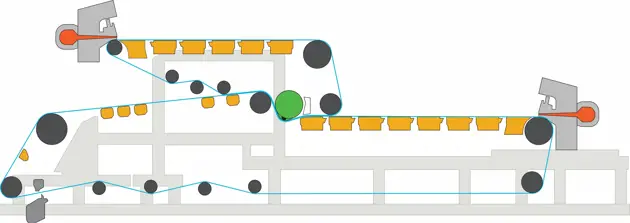

Sleeve roll in multi fourdrinier forming section, combining position

This production machine produces test liner grades in basis weight range from 115 to 250 g/m², with design speed of 1,000 m/min. In this project a multi fourdrinier forming section was rebuilt with Sleeve roll in the combining position. The rebuild target was to improve bonding of the two combined plies and at the same time increase machine capacity. Both of these targets were achieved.

Sleeve roll on board gap former - vacuum reduction test run

What happens on a board gap former if initial forming section vacuums are turned off? The answer is groundbreaking results, if the forming section is equipped with innovative Sleeve roll technology.

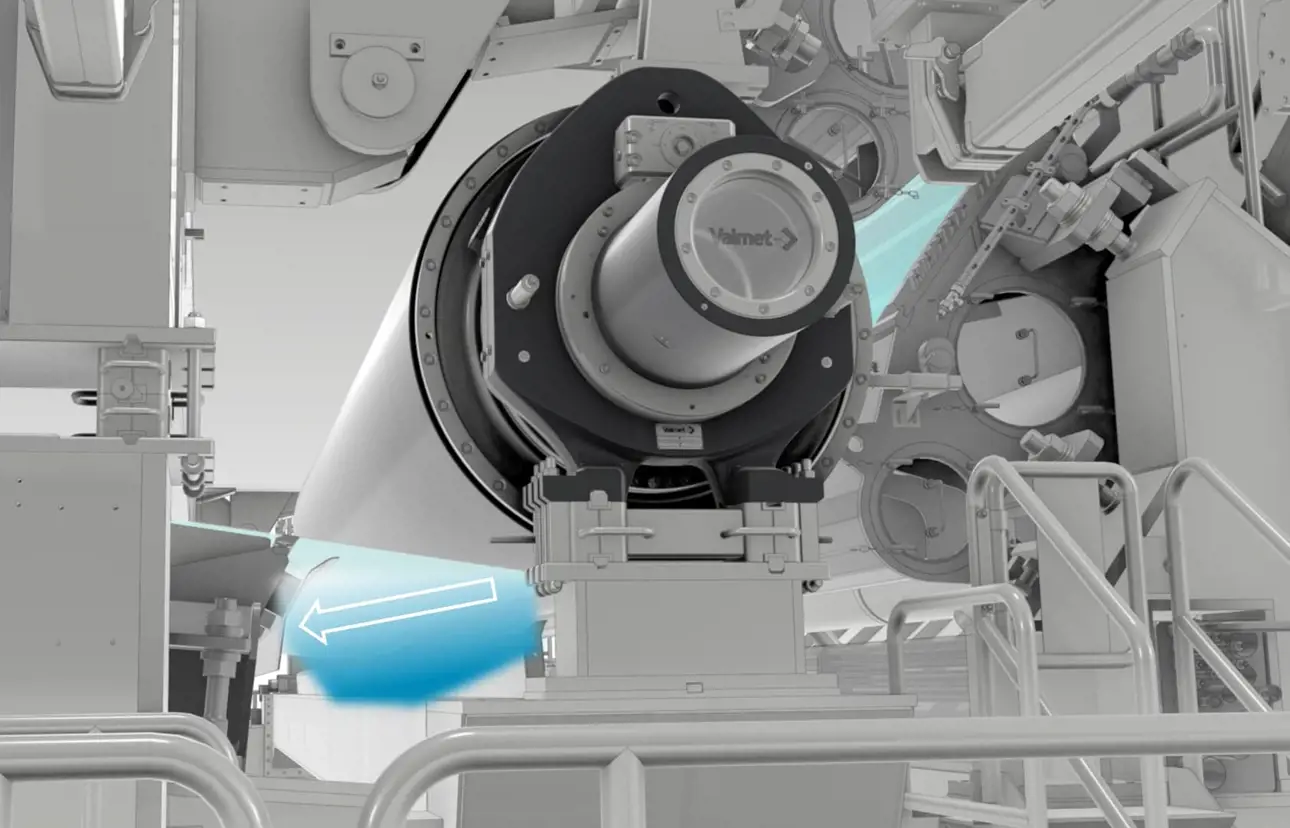

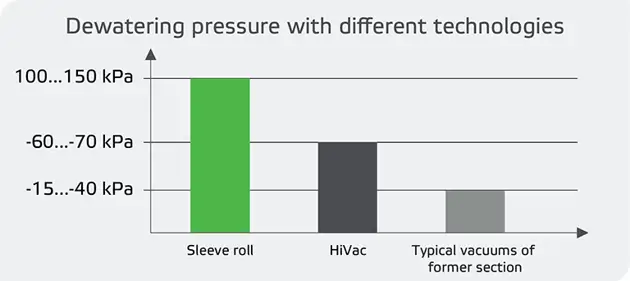

As mentioned above, Sleeve roll technology is disruptive and transformative forming section technology that deploys the principles of pressing already in the forming section. A fiber web is compressed between two forming fabrics against a small radius shoe, which creates a very high dewatering pressure of up to 150 kPa.

Have a look on the video a vacuum reduction test run on board gap former with Sleeve roll technology to see the results yourself.

The Sleeve roll dewatering principle

At the core of Sleeve roll's brilliance lies its dewatering principle. The idea is to compress a web between two forming fabrics against a small radius shoe. With this innovative technology the Sleeve roll achieves remarkable dewatering pressure levels of up to 150 kPa. With conventional forming section technologies, dewatering pressure is typically around 15 to 40 kPa, and with a couch roll or HiVac, it is typically around 60 to 70 kPa.

With the basic circle before the shoe of the Sleeve roll, the fabric tension creates moderate pressure. When passing over the variable radius shoe, the dewatering pressure increases steadily toward the maximum compressing pressure. The steadily increasing dewatering pressure in the Sleeve roll shoe causes no defects to the web, even with very low ingoing consistency.

This gentle yet effective approach of the Sleeve roll technology harnesses fabric tension and shoe interaction to gradually escalate dewatering pressure. The outcome? Efficient water removal without compromising paper integrity.

Unlike conventional methods that rely on vacuum systems, Sleeve roll's clever design minimizes friction and eliminates the need for a vacuum in the forming section. This translates to impressive energy savings and contributes to a greener manufacturing process.

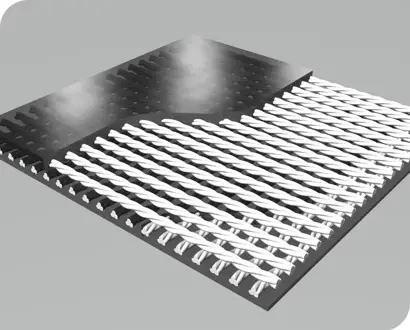

Valmet Sleeve Roll Belt

An essential part of Sleeve roll technology is the elastic and durable polyurethane belt rotating around the roll. Valmet Sleeve Roll Belt is designed especially for this roll technology where the belt and forming fabric need to work together. The belt responds to the strict requirements (e.g. hardness, roughness, elasticity) of both the belt oil side and paper side surfaces.

How do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookServices solutions for forming sections

Explore our latest board and paper press releases

- Jan 29, 2026Valmet launches new Bioneer press roll covers with reduced climate impact

- Dec 19, 2025Muoto products produced with Valmet 3D Fiber technology piloted at Valmet’s Jyväskylä location

- Dec 8, 2025Valmet has completed change negotiations for temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Nov 26, 2025Valmet supports Wuzhou Special Paper’s transition to recycled board grades with a complete paper machine conversion rebuild

- Nov 5, 2025Valmet to start change negotiations regarding temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2