Microwave dry cake solids measurement

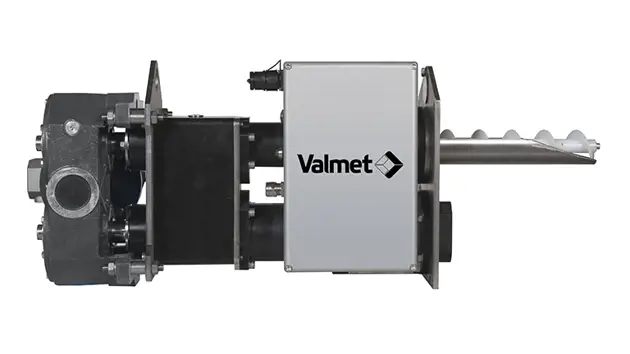

Valmet Dry Solids Measurement - Valmet DS

The Valmet Dry Solids Measurement (Valmet DS) is engineered for dried wastewater sludge (dry cake) optimization. Accurate online measurement of solids from Valmet DS provides significant savings opportunities.

Minimize transportation costs of dry cake and side fuel cost with maximized total solids

Enable dewatering process optimization to save energy and improve efficiency

Enable better further processing of dry cake with optimized cake solids

Significantly reduce polymer consumption by optimizing dosage and centrifuge torque.

Maximize solids in dry cake for transport savings

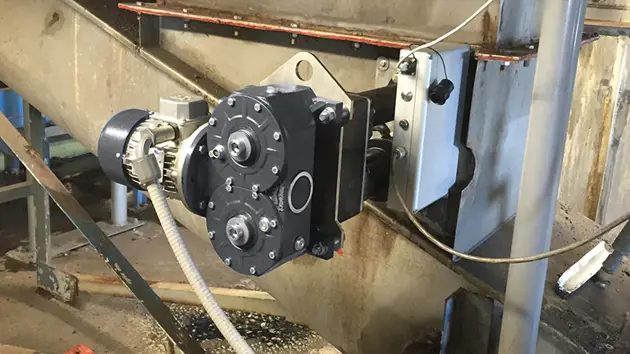

The unique Valmet DS utilizes safe microwave technology to make a stable and accurate solids measurement for dewatering control in wastewater treatment. Typically located in the vertical section after a centrifuge, screw or filter press, the Valmet DS extracts a continuous sample from the falling cake flow.

Valmet DS uses sophisticated microwave technology to determine the exact cake solids up to 35%. Using the accurate dry solids measurement provided by Valmet DS, operators can fully optimize dewatering. When it comes to transportation expenses, dry cake optimization results in extreme cost reductions. Higher cake solids drive down the volume of cake that needs to be hauled away from the plant.

Optimize energy use and production

Decanters and centrifuges consume lots of power. The Valmet DS helps you manage that energy demand by enabling direct comparisons between solids output with energy consumption in real-time. Optimize solids level versus consumed power and confidently run with the ideal balance.

Maximizing drying efficiency to a target dry cake solids content also provides additional savings with improved power boiler combustion. A dry cake that is further processed, such as for biogas production, often needs to be in a certain solids range to be acceptable. The Valmet DS helps you keep your dry cake on target, ensuring it isn’t too high or too low for the next processing phase.

Reliable online measurement

The consistently accurate Valmet DS measurement is based on multivariable microwave resonance. Initial calibration is based on samples during commissioning, while variations in material temperature are automatically compensated for during production use.

Industrial Internet support gives you full remote access to Valmet DS functions, measurement data, alarms and diagnostics. The Valmet DS has an optional local display panel and includes an ethernet port for local control with a laptop. A simple Windows application offers quick access to status, a built-in, easy-to-use auto-calibrator and essential troubleshooting tools.

Solids Measurements For Better Wastewater Control

Download Valmet Wastewater Guide to learn how reliable online solids measurements can be used to optimize and improve plant operations and process.

Download

User Manuals

In our Customer Portal you will be able to find the user manuals you are looking for. The manuals are available in several languages and can be easily downloaded.

Customer Portal