Valmet Service Centres in Haslingden and Darwen, UK

Valmet in the UK offer high-quality reliable services for board, paper, tissue, pulp and energy industries as well as for rubber and plastic, printing, converting machinery, cement industry, waste and steel industry.

Services offering for board, paper and tissue industry

Valmet’s Roll Service Centre located in Haslingden offers workshop and on-site services, including 3D roll grinding, roll refurbishment, high quality balancing and thermal spraying for paper, converting and packaging as well as other process industries.

The machine shop at Haslingden is well equipped to handle long turning jobs, such as drive shafts and paper machine rolls. Excellent milling and boring facilities utilising large capacity machinery operated by highly skilled personnel provide exceptionally versatile refurbishment services. Our service-facilities include equipment for profiling and taper grinding of cylindrical components up to 11 meters in length and 1.8 meters diameter, with matching capacities for dynamic balancing. We can also use our unique range of on-site grinding and super-finishing equipment, for in-situ service of larger components to the same exacting quality standards.

Solutions and services for your equipment close to you

Solutions and services for your rolls

- Roll maintenance services

- Roll reconditioning services

- Roll upgrades

- New rolls

- Roll covers

- Composite covers

- Polyurethane covers

- Rubber covers

- Thermal spray hard covers including release coatings

- Workshop services for you mill's needs

- Heavy machining

- Heavy grinding

- Thermal spray component repairs

- Dynamic balancing and testing

- Thermal-Spray coating – for dimensional reclamation, restoration of worn, damaged or mis-machined surfaces, and to impart other valuable surface qualities

Local sales, projects, engineering and field maintenance services operate from the site in Darwen, as well as the international activities of machine relocation and Yankee services.

Field services

- Comprehensive process solutions

- Field services such as shoe-press overhauls, on-site coating, headbox services, alignment services, on-site grindings

- Advanced machinery maintenance

- Process development services

- Technology support

- Doctor maintenance

Spare and process parts

Ease of purchase, reliable and prompt logistics and information sharing are all key requirements for the efficient management of wear and spare parts. We offer a full range of engineered and replacement parts, as well as spare parts packages and process parts to ensure the optimal runnability and maintainability of production lines while also minimizing maintenance costs.

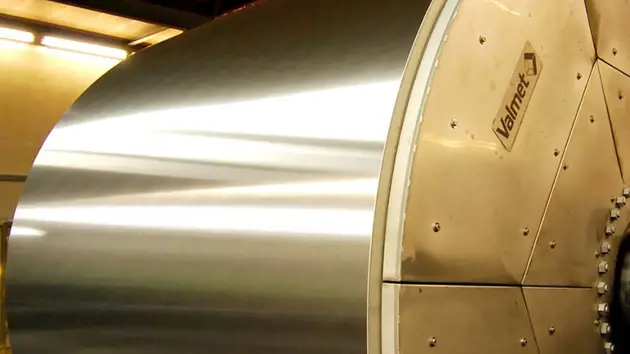

Yankee resurfacing services

The Yankee surface is critical for tissue making and even small marks on the surface can cause severe damage to the paper web. Depending on the degree of damage, different methods to restore the surface become applicable.

Localized defects, grooves or scratches can mostly be removed by polishing. Damages like deep chatter marks, corrosion or wear requires on-site profile grinding to restore the optimum shape of the Yankee cylinder.

Valmet offers the following Yankee services to create the perfect Yankee surface, ensure optimum performance and extended service life:

- Yankee surface polishing

- On-site Yankee profile grinding

- Thermal coating

Yankee surface polishing - removes build-up and slight chatter marks

Screen cloth removes non-uniform organic coating and hard build-up on the cylinder edges and helps to establish a uniform surface finish. It is easy to apply and prevents crepe blade vibrations, sheet holes and edge breaks due to build up.

The Yankee surface polishing (RSG) is recommended to restore the surface integrity, remove local defects, grooves, scratches and dents. The (RSG) polishing makes it possible to remove defects up to a depth of 0.2mm.

On-site Yankee profile grinding - removes severe surface defects and fully restores the cylinder profile

Yankee profile grinding is suited for more severe surface defects, chatter marks of more than 0.2mm depth and wear resulting in a loss of the ideal Yankee surface profile.

The grinding equipment can be installed either in the suction press roll or doctor position. It provides high accuracy and grinding quality.

Thermal coating - perfect condition and prolonged lifetime

The application of Valmet Infinikote Yankee Metallizing provides an excellent Yankee surface, reduces the frequency of regrinding and greatly extends the life of the Yankee.

A hard, protective coating with a homogeneous surface, good bond strength and high corrosion resistance. It is very reliable and unsurpassed in thermal coating life, heat transfer, blade life and Yankee surface efficiency.

Machine relocation services

Our experienced and qualified team based in the UK can deliver complete shipping and installation solutions combining relocated or new machinery for delivery worldwide. We have extensive experience of successfully dismantling and reassembling plant and industrial equipment of all sizes and complexities within the Paper, Tissue, Food Processing, Converting, Printing and other industries.

Our meticulous machinery matchmarking process ensures everything is in order for reassembly anywhere in the world, with detailed, easy to follow documentation. Complete turnkey solutions ensure all machinery and equipment can be installed in a new location in the same condition as the original installation

- Comprehensive process solutions

- Advanced machinery maintenance

- Process development services

- Technology support

- Spare parts and process parts

- Rebuilds and upgrades

- Inspection

- Service Agreements

- Full O&M service - providing output availability and efficiency guarantees.

- Long Term Service agreement, LTSA – providing fixed price maintenance costs for your asset.

- Service Level Agreements, SLA - defined services with performance guarantees.

Our proven track record in many different industrial environments and cultures are evident with successful contracts completed in the United Kingdom, Republic of Ireland, Australia, New Zealand, USA, South America, France, Italy, Hungary, Switzerland, Sweden, Philippines and China.

Contact details in UK

Darwen service center

Waterside Business Park

Johnson Road

Darwen BB3 3BA

United Kingdom

Haslingden service center

Manchester Road

Haslingden, BB4 5SL

United Kingdom

Phone: +44 (0) 1254 819050

Email: ukinfo@valmet.com

Roll workshop

Steve Walls

+44 7711 172154

steve.walls@valmet.com

Sales contact

Matt Lees

+44 7741 082769

matthew.lees@valmet.com

Relocations

Yankee services

Chris Mannion

+44 7824 140097

chris.mannion@valmet.com

Maintenance

Mike Sword

Manager, Field Services

+44 7974 415697

mike.sword@valmet.com

Spare parts

Sandra Bennett

+44 7725 672285

sandra.bennett@valmet.com

Power plant services UK and Ireland

Nigel Earp

+44 7768 888926

nigel.earp@valmet.com