Improve safety at your boiler with a furnace inspection camera

Maintaining safe, efficient and environmentally compliant boiler operations is very important. However, doing so is difficult when operators simply look into ports and make educated guesses about the boiler situation.

Valmet offers a Valmet Furnace Imaging System to improve the quality of the decision-making process with respect to boiler operation. The system allows Valmet field service engineers to find ways to optimize boiler fuel introduction, whether solid, liquid or gaseous in order to optimize efficiency. It also provides the tools to locate and diagnose firing issues and ensure environmental compliance.

Valmet Furnace Imaging System, Portable Mid-IR

The system is available in either a straight lens (Figure 1) or a rotating off-axis lens (90°) which allows the Valmet engineer to rotate the camera lens 360° around the camera axis. The camera system can be operated in air ports, observation ports, and manways and can be installed in most operating boiler environments. The camera lens is air-cooled and its temperature is monitored by an onboard thermocouple.

Figure 1. Valmet Furnace Imaging System, Portable Mid-IR

The system has a built-in video display and can also be connected to a portable DVR equipped with an 8GB memory card. Using this, the Valmet engineer reviews footage to pinpoint boiler problems. The engineer can then demonstrate firing issues to mill management and operations personnel, as well as the results of corrective operational changes.

Examples of use

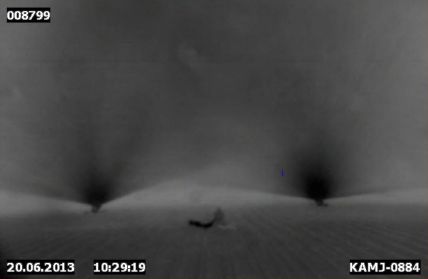

In the examples shown in Figures 2 and 3, the system uses a rotating off-axis lens assembly looking downward from the quaternary air port level. There are two liquor guns on the front wall. The tertiary air port is located in the center of each image. Figure 2 shows a poor spray pattern resulting from dirty liquor sprays (timestamp 10:27:15). Figure 3 is from the same viewpoint, but the liquor sprays are clean and the subsequent spray pattern is smooth (timestamp 10:29:19).

Figure 2 Poor spray pattern results from a dirty liquor spray.

Figure 3 Clean liquor sprays provide good spray patterns.

Other uses of the Valmet Furnace Imaging System, Portable Mid-IR include:

- Viewing heat transfer surfaces for deposition and pluggage

- Locating and viewing upper furnace deposits in the front roof corners (floor damage)

- Using the straight lens assembly to look into the leading superheater passes for plugging

- Watching sootblower action

Valmet’s Field Service Engineering and the Mobile Inspection Camera System allow mill operation staff to see and correct the causes of boiler firing issues. With extremely accurate data about boiler operation, mill personnel make safer and more efficient boiler operation decisions.

For more information on improving your boiler safety, efficiency and environmental compliance, contact your Valmet representative.