Valmet Recovery Boiler Cleaning - simple, efficient and safe

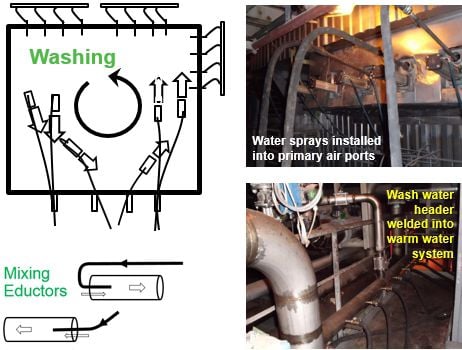

Valmet has developed a recovery boiler floor washing service called Valmet Recovery Boiler Cleaning. With this service the floor is washed simultaneously with the rest of the boiler using low pressure water sprays and mixing devices installed on the furnace floor. Valmet Recovery Boiler Cleaning decreases and possibly eliminates the need for mechanical cleaning and high pressure washing of the floor. As a result, this also significantly reduces the risk that floor tubes are damaged during cleaning.

Overview of the process

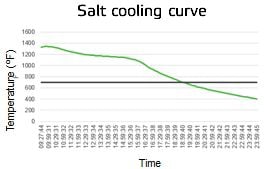

Water is sprayed onto the floor as soon as safe bed temperatures have been reached. Water can be sprayed to the furnace floor through liquor guns or nozzles installed in multiple openings. Several water sources can be used: feedwater, condensate, warm water and fire water.

Overview of the Valmet Recovery Boiler Cleaning process

Mixing devices (eductors) are installed on the furnace floor and operated continuously throughout the entire boiler washing period. Once the superheaters are clean, the mixing devices are removed and floor is emptied of wash water using the Valmet Smelt Extraction ejectors.

Valmet Recovery Boiler Cleaning prerequisites

- Pressurized air (approximately 90-100 psi)

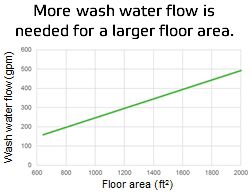

- Warm water that can be pumped into the furnace floor while other parts of the boiler are being washed: water temperature 120- 160°F (50-70°C), water flow 250 g/m per 1000 ft2 of floor

Total water consumption can be minimized, if needed, so that wash water is removed from the floor only when the density is high (salt content 20%). This may require heating the water pool with steam or hot water because extended circulation may be required, and mixing with pressurized air may cool the pool. However, some water must be sprayed so that the deposit pile is dissolved as quickly as possible

Salt concentration is used to monitor washing effectiveness

Hot water results in faster washing. Hot water may also be needed to dissolve large ash deposits which fall to the floor.

The wash pool volume protects the floor from large falling deposits.

Wash salt concentration density is periodically measured.

If the wash water density increases above 1.25, a higher wash water flow is likely to be beneficial. Densities below 1.1 indicate that the wash water flow rate can be reduced without any significant reduction in the dissolving rate.

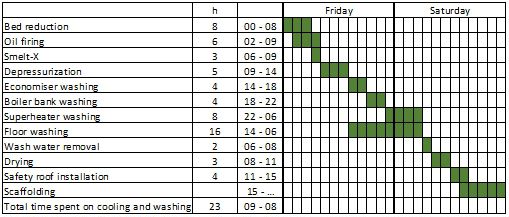

Planning

A detailed plan for wash water spraying is made in co-operation with the customer so that the equipment needed will be available in time.

Typical time schedule for Valmet Recovery Boiler Cleaning service

The customer is responsible for supplying the required water to wash the floor.

Some customers have wash water systems already in place. In this case Valmet operates the wash water system, including sprays, and the mixing eductors during washing.

Information needed from the customer:

- availability of warm or hot water (flow rate, total amount, temperature)

- the expected amount of ash deposits (expected pile height and area)

- schedule for boiler washing

- equipment available from the customer (if any)

For information on safer and effective cleaning of chemical recovery boilers, contact your Valmet representative.