Superior quality and decreased raw material costs with metal belt calendering

OptiCalender Metal Belt calender

The unique OptiCalender Metal Belt features a long-nip calendering technique that provides boardmakers with a major quality and efficiency boost. The possibilities to increase profit with very high surface quality and decrease raw material cost with the increased bulk are evident.

Higher bulk = less raw material and increased profit

High end product quality with premium price

Production increase

Easy to operate and maintain

Extremely long dwell time and the most effective plasticization

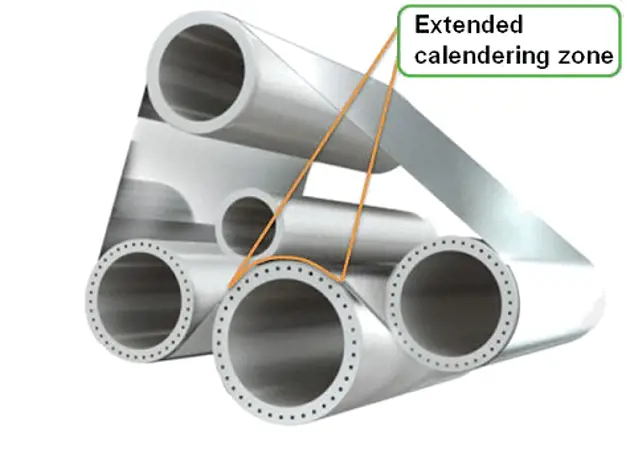

The secret behind OptiCalender Metal Belt calender lies in two factors; an extremely long dwell time and the most effective plasticization. OptiCalender Metal belt’s dwell time is 4-15 times longer than with a shoe nip calender and 100 times longer than with a conventional soft nip calender. Effectively plasticized surfaces provide low surface roughness values, good printing quality and a low post-roughening tendency after calendering.

With OptiCalender Metal Belt, the traditional calendering nip has been replaced with a one-meter-long machine-direction calendering zone. The OptiCalender Metal Belt has a smooth, heated metal belt and a thermo roll that calenders both web sides simultaneously in one extended zone.

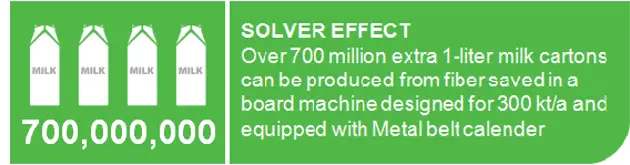

Higher bulk => less raw material, increased profit

Metal belt calendering is the ultimate method for bulk saving. It allows significantly higher heat transfer and plasticization, resulting in extremely high bulk and stiffness. Thanks to its one-meter-long processing zone, superb printing quality is achieved while maintaining high strength properties. This enables raw material optimization with savings potential – as much as 10% higher potential than with a Yankee cylinder. Consequently, this generates substantial raw material savings and increases yield.

The numbers behind fast payback are hard to believe. The saving potential with production increase, raw material savings and bulk saving can be counted in millions. An article about Zhuhai S.E.Z. Hongta "How about saving millions?" clarifies these figures almost too hard to believe.

Want to talk to our calendering experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsHigh end-product quality

In terms of surface properties, the formation scale smoothness is improved, resulting in extremely flat and smooth surfaces and enhanced visual appearance on both sides of the board. For converters, this means excellent printability and consistent ink setting, as well as a decreased tendency towards print mottling.

By using OptiCalender Metal Belt, the board surface quality is outstanding:

- Excellent macro scale smoothness

- Even topography after coating

- Better optical properties

- Excellent macroscale topography with same or better stiffness.

What more can you hope for? We invite you to carry out your calendering trials at Paper Technology Center. All calendering technologies can be tried out with your own paper or board.

Production increase

Thanks to its simple and compact design, the OptiCalender Metal Belt is especially suitable for rebuilds. The calender provides 40 - 60 % more production by removing existing bottlenecks, such as the Yankee cylinder and wet stacks.

Easy to operate and maintain

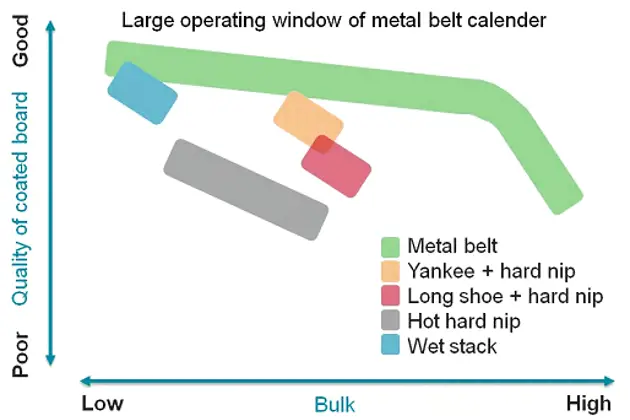

OptiCalender Metal Belt is easy to use. Linear load is the only control parameter that needs adjusting in the calendering process. Two-sidedness can be controlled with temperature. Also the operating window is large. The example in the figure below shows the comparison of coated board calendering (the quality level and bulkiness).

The calender maintenance is also easy because of the opening front. Additionally, the metal belt life time can reach even two years (see article about metal belt lifetime record).

Former ValZone metal belt calender has been included in the OptiCalender family as OptiCalender Metal Belt.

Customer success stories and articles

Planning a grade conversion?

The world is changing fast; the consumption of newsprint and printing paper is decreasing and the consumption of containerboards or cartonboards are increasing. An old paper machine can be updated with a grade conversion rebuild to produce more profitable products. Turn a new page for your paper machine with the help from Valmet.

Discover moreHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookInterested in pilot trials?

We offer the opportunity to experiment and develop paper and board products and processes without having to put your own production on hold. This is very cost-efficient compared to expensive tests in your own production. Follow the activities in the trials on site or remotely through live streaming cameras.

Contact our pilot trial expertsLearn more about the services and automation solutions for calenders

Explore our latest board and paper press releases

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China