Calendering in compact size for maximum usability with minimum operational costs

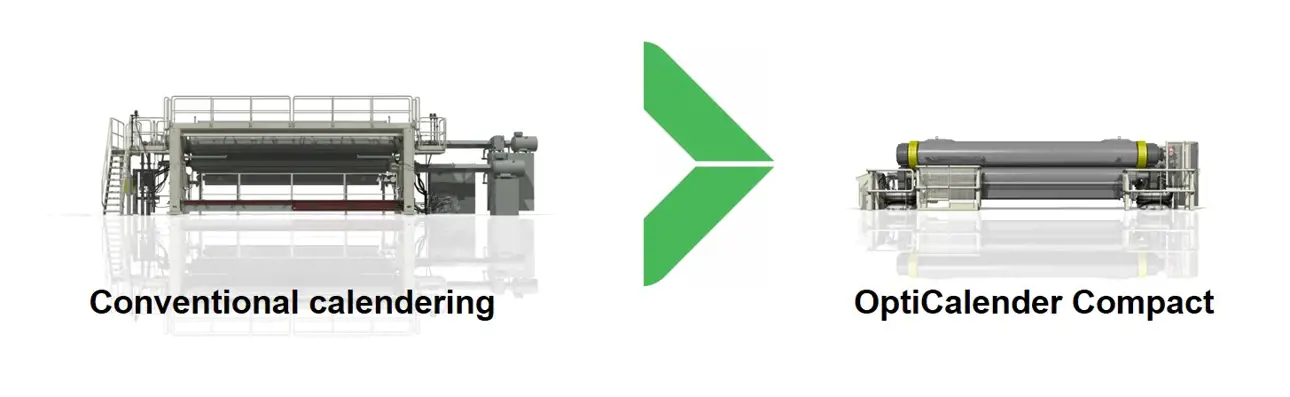

OptiCalender Compact – hard and soft nip calendering

OptiCalender Compact is designed for maximum usability with minimum operational costs. It provides quality calendering, but its structure is greatly simplified compared to your average calender. The simple, integrated structure enables extremely easy start-ups, everyday site operations as well as maintenances. Naturally, this also lowers the required initial investment and operational costs.

Lower initial investment and operational costs

Fast and smooth delivery

Compact size - everything integrated into the machine frame

Easy commissioning and start-up

Standardized project → a fast, smooth delivery

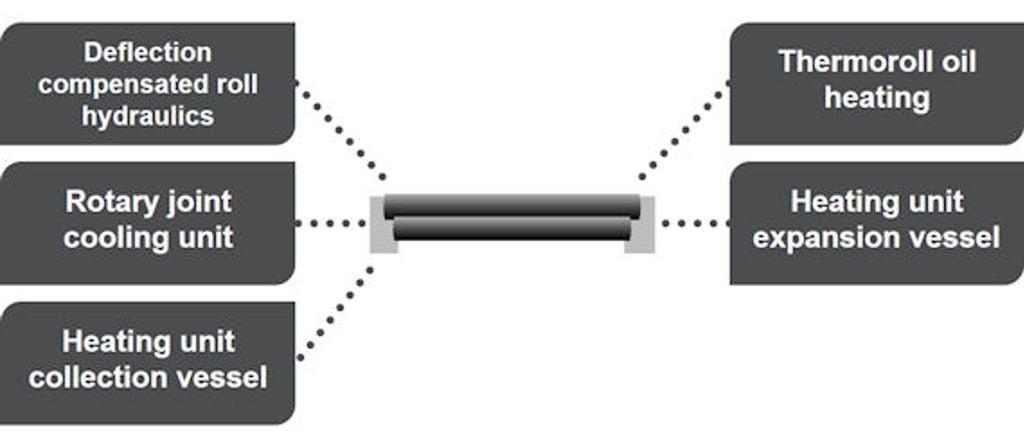

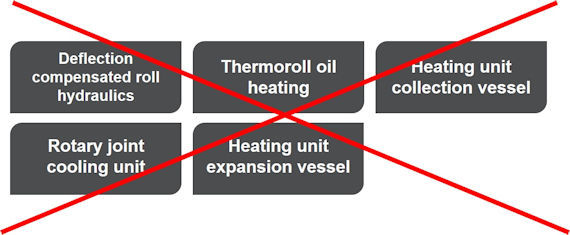

When you need a new calender, the whole calender delivery project is standardized from start to finish to ensure a fast, smooth delivery. All components have been designed to function together seamlessly, which limits the amount of modifications available for this calender model. However, with a more fixed calender module it is possible to integrate all parts of the design into one single unit. This way, no additional devices need to be placed in the basement or, for example, a separate automation module.

Want to talk to our calendering experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsEverything integrated into the machine frame:

No separate modules nor devices in the basement

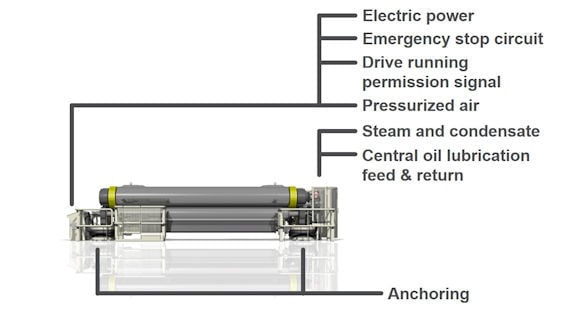

Below are all the connections that need to be made on site and after that the calender is fully operational. There are no separate hydraulic power units, drives or other equipment. No additional devices need to be placed in the basement or a separate automation module.

New way of thinking in calender design

There are several structural improvements including walkways and drive foundations. The integrated drives don’t require any alignment or foundation building at customer site. All machine controls have been built into the calender control panel. All the pumps and valves required to controlthe machine’s pneumatics and hydraulics are located inside the control box.

Also the roll is heated by steam to increase cost efficiency. Similar structure is used in dryer cylinders - numerous references available. The integrated heating system uses paper making line steam supply.

Easy commissioning and start-up - Calender connections at the site:

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreLearn more about the services and automation solutions for calenders

Explore our latest board and paper press releases

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China