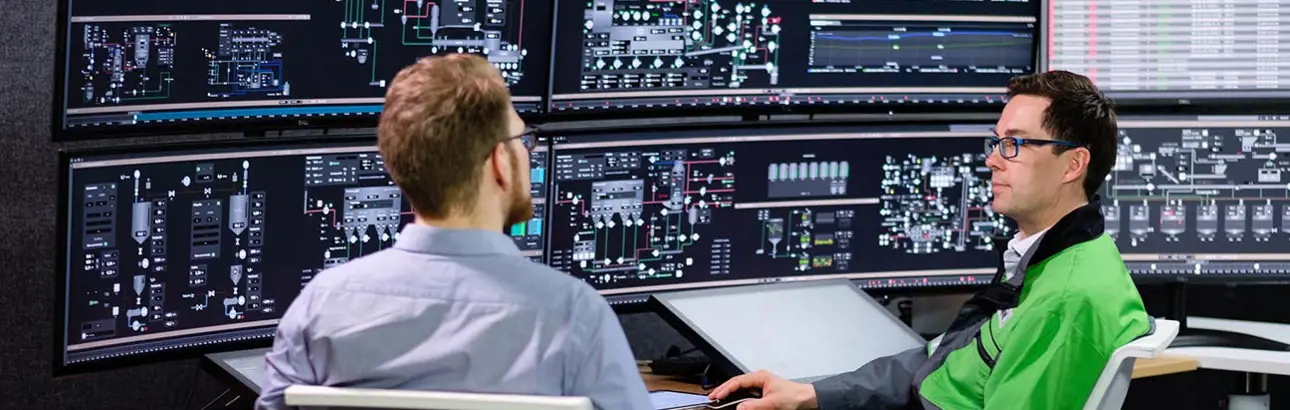

SCADA solutions

Valmet DNA Distributed control system

Supervisory control and data acquisition, SCADA, is a way to control and monitor various industrial processes. SCADA enables monitoring and controlling of the plant operation remotely. SCADA is not limited to a specific technology. Instead, SCADA is a type of automation solution that provides additional value to its stakeholders with the help of technology.

Valmet DNA technology ranges from small stand-alone and plant-wide systems to geographically distributed SCADA solutions that support global organizations and operational excellence.

Benefits of Valmet DNA SCADA solutions

- the flexibility to interface automation systems from multiple vendors to a

single centralized control room - modern easy to use user interface

- advanced alarm, trending and reporting capabilities

- various protocols available for interfaces

Valmet DNA technology is used for demanding automation solutions. It combines controls, data acquisition, performance monitoring, optimization, graphical user interface, engineering and asset management into a single user-friendly automation platform.