Optimize doctoring performance and lower total cost of ownership

Every doctoring process can be improved. The usual investments required are minimal. Optimizing your doctoring processes results in better runnability, improved quality, optimal production efficiency, reduced maintenance costs and improved safety and environmental effect.

Benefits of a Valmet Doctoring Services Agreement

- Cost savings

- Inventory management

- Improved blade life and product quality

- Minimized sheet breaks

- Longer machine clothing life

- Improved runnability

- Improved roll cleanliness

- Minimized maintenance time/need

A webinar about Valmet Doctoring Services Agreements was held on October 21st, 2020 and is available HERE.

Partnership and consignment program

A Valmet Doctoring Services Agreement is a partnership program between the mill and Valmet to improve overall performance of the machine, reduce downtime and maintenance costs through improved roll doctoring. The program includes doctoring audits, recommendations for improvements, blades, storage and blade handling equipment to reduce safety incidents, optimize blade performance and reduce the total cost of ownership.

The program also includes inventory managment which can be integrated with mill ERP systems. We organize the entire doctor blade program from ordering, inventory and installation. Our system provides identification of machine and position to ensure the correct blades are on hand for every position and are installed in the proper locations. The Valmet Doctoring Agreements can further include services such as:

- monthly blade inventories to make sure the mill does not run out of blades

- assisting to solve doctoring problems

- training operators in the proper use of blades

- helping to create safety procedures and standard working procedures

- discounting doctor blades and all types of holders, including composites

- shutdown services such as changing hoses, holders and bearings

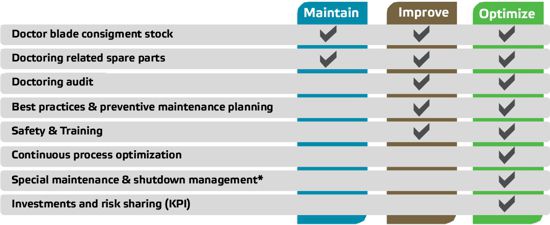

A Valmet Doctoring Services Agreement is customizable. (* not available in all regions)

Agreements provide solutions

Typical solutions achieved by mills using a doctoring agreement include:

- increasing operator safety

- savings and improvement possibilities with continuous optimization

- improving blade life and product quality through materials and training

- recycling and regrinding of blades

- optimization of carbon content in doctor blades

- optimizing loading pressure, doctor blade angle, doctor blade holder, lubrication and shower setup

- optimization of doctor beam and oscillation

- choosing the best doctor blade for each application

Here are just a few of many positive results mills have achieved with a Valmet Doctoring Service Agreement:

Target: Eliminate problems with severe fiber buildup behind the blade and dirty cylinder surface.

Results:

- 50% longer blade lifetime

- Annual blade cost reduction 24%

- Visually cleaner cylinder surface

- Less fiber build up behind the blade

Target: Resolve problems of pre-dryer breaks, occasional fiber passing problems and holes detected in paper.

Results:

- Improved doctoring result and less doctoring-related downtime

- Remarkably reduced holes in paper, resulting in 30% break reduction in dryer section

- Easy holder maintenance and spare parts

Target: Increase center roll blade lifetime to match maintenance shut down interval.

Results:

- Blade lifetime increased from 8 days to 14 days

- Blade cost reduced by 50%

- Produces 500 tons/yr more board

Target: Customer had lost 20+ dryer fabrics in two years due to paper pass-throughs.

Results:

- Dryer section doctoring cost remained at the same level

- No dryer fabrics have been lost after improvements, savings of roughly 225 KUSD per year

Target: Increase dry content after the former.

Results:

- Over 110 KUSD annual compressed air savings

- 0.5% dry content increase after the former

- 100 m/min speed increase

- 30 tons/d production increase

- 0.5% increase in dry content

Target: Lower the annual blade cost.

Results:

- Doctoring cost decreased by 135 KUSD (from 200 KUSD down to 65 KUSD)

- 50% lower doctoring cost

Efficient doctoring increases productivity

Valmet keeps the doctoring process of paper and board machines running efficiently all the time. To do this, it is important to use the best doctoring blade material and to correctly handle the doctor blades. Valmet looks after this for you and will supply the appropriate blades for each machine position as well as training and consulting.

Available 24/7

Training, consulting, and service are available 24 hours every day. Valmet ensures that your doctoring process runs smoothly and efficiently.

For more information on improving doctoring performance while lowering total cost of ownership, watch the webinar and contact your Valmet representative.