Valmet Double Doctor significantly reduces sheet breaks

Iggesund Paperboard installed Valmet Double Doctor* solution, with the result that the board machine is running more stably and with less downtime.

Iggesund Paperboard’s board machine BM 2 had been experiencing problems with doctoring in recent years, which had been the main reason for sheet breaks in the machine. Single doctoring was not able to keep the third press top roll clean, which led to build-ups, causing holes in the sheet that led to breaks in the calender. BM 2 had eight sheet breaks a month, and it took on average an hour to come back to prime quality production each time.

Based on this situation, the company appointed a project group, and different suppliers were invited to present solutions to the problem.

No more breaks due to pulp build-up

“The reason why we chose Valmet as our supplier is that their solution impressed us and Valmet gave a very professional impression of themselves,” says Stefan Johansson, Production Engineer of BM 2. Valmet carried out a pre-study during one day to be able to offer a tailor-made solution.

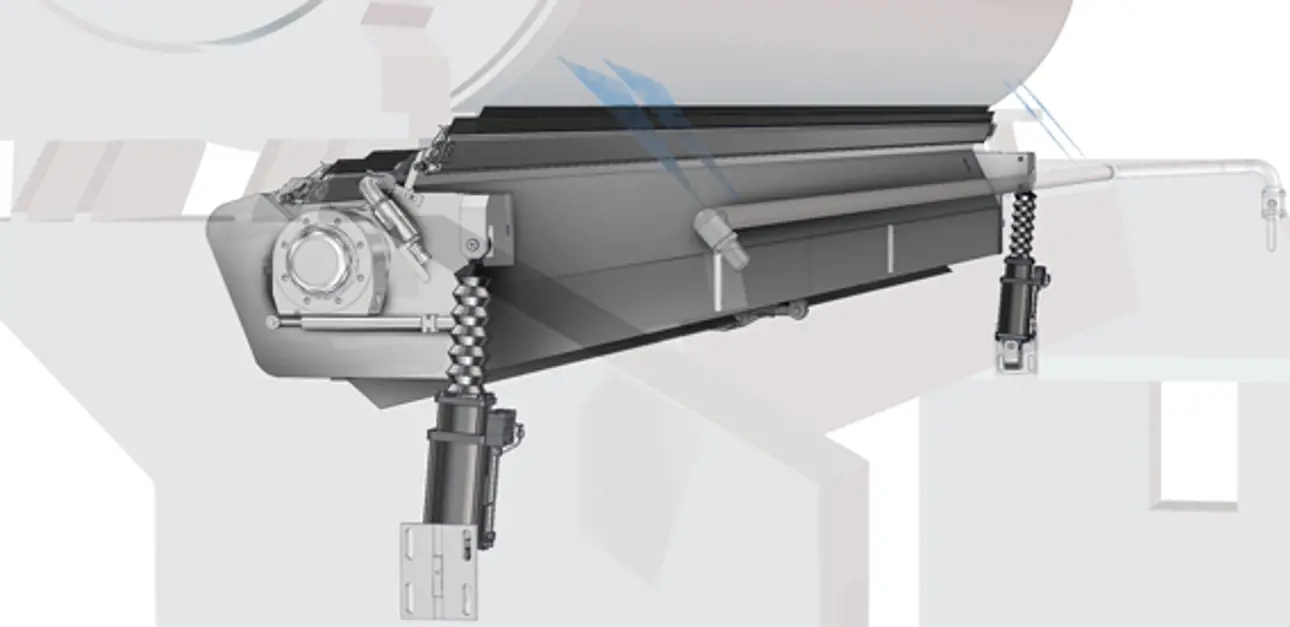

The contract for the new doctoring solution was signed in June 2015, and the installation took place during a pre-planned, five-day stop in November. Valmet’s own assemblers were responsible for the installation of the double doctor. It went smoothly and only took three days. After the installation, one assembler stayed onsite to participate in the start-up of the machine. Valmet Double Doctor started with two doctor blades, Valmet Doctor Blade Carbon VC** and Valmet Doctor Blade Carbon VT ***, which were included in the delivery.

With Valmet’s double doctor, there are no more breaks due to pulp build-up from the third press. These days, the second blade collects any build-up that might pass the first blade. The changing interval for the doctor blades is six weeks. As the new doctoring unit is larger than the previous one, there was a slight worry that it would affect the tail threading in a negative way, but it has worked without any problems.

“We are very happy how the project turned out, from the first contact with Valmet to the start-up. Apart from a few adjustments at start-up, we haven’t had any downtime due to the doctoring,” says Johansson.

|

||

| Stefan Johansson, Production Engineer of BM 2. |

Iggesund Paperboard is an integrated pulp and board mill using its own chemical pulp. |

|

|

Iggesund Paperboard is situated in Hudiksvall, in the north of Sweden. It is an integrated pulp and board mill with its own chemical pulp. The mill produces solid bleached board (SSB) for graphic design packaging for the food, tobacco and cosmetic industries. Board machine BM 2 produces 195,000 tonnes of paper a year with a basis weight range of 180–380 gm2 at a speed of 550 m/min. The third press section was originally equipped with a single doctor blade. |

*earlier known as DoubleDoc

**earlier known as ValCar

***earlier known as ValTech