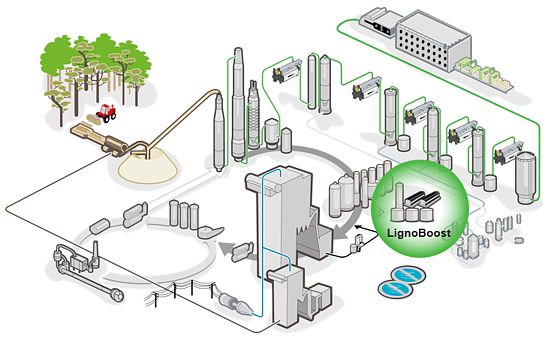

The next generation LignoBoost, tailor-made lignin production

The list of end products that can be made from lignin ranges from fuel applications to carbon fibers and fine chemicals. Commercial and high purity lignin from the LignoBoost process is produced worldwide and sold globally. Add on processes are developed for the lignin bio-products market in order to meet various specifications.

As more lignin becomes available on the market one key question that must be addressed is: What to do with the produced lignin? A white paper found HERE describes highlights and important results from collaborations aimed to develop add-on processes that will produce lignin with a tailored specification.

LignoBoost is located close to evaporation.

It has been shown that the compound contributing the most to the characteristic smell of lignin is not the sulphurous compounds; it is guaiacol. By decreasing the guaiacol content in the lignin from 1.42 mg/kg to 0.04 mg/kg an odor free lignin can be produced. This means that a completely odor free biocomposite could be produced from lignin. The odor free lignin concept is ready for commercialization.

Lignin can be tailored to meet several quality specifications. A bio based carbon product can be produced from lignin by hydrothermal carbonization. The product could be used as reinforcement filler in rubber products or be activated and used in e.g. gas cleaning.

By jointly collaborating to commercialize lignin quality, it is possible to:

- Add revenues for all development partners

- Increase product diversification

- Minimize dependence on fossil raw material use

- Decrease time to market for high value lignin qualities

For more information about lignin production and its profitable uses, read the white paper and then contact your Valmet representative about the LignoBoost process.