Stonel™ Axiom™ AX explosionproof

Discontinued product

Superseded by Stonel Axiom ANX models and mounting.

Specifications

|

AX33/ AX35:

|

Universal voltage switching and solenoid

|

|

AX44:

|

Namur sensors (7-24 VDC)

|

|

Communication options:

|

AS-Interface, FOUNDATION Fieldbus, DeviceNet and HART

|

|

Temperature range:

|

-40 °C … +80 °C / -40 °F ... +176 °F

|

|

Material:

|

Epoxy coated anodized aluminum or 316L stainless steel

|

|

Flow capacity:

|

0.7 Cv or 1.2 Cv

|

|

Hazardous area approvals:

|

Ex d, Ex i, Class I, Division 1 and Class I, Division 2, see Approvals tab

|

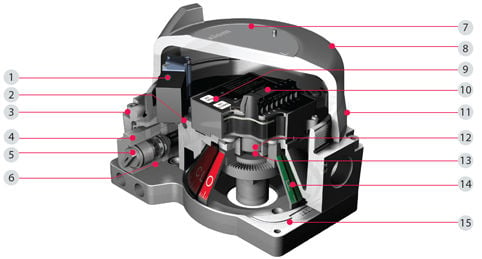

1. Universal burn out proof solenoid operates on less than 0.6 watts of power and standard version will accept 24 VDC or 120 VAC, reducing stocking requirements.

2. Prefiltered pilot valve provides additional protection from contaminants.

3. Easy removal from automated valve package is accomplished with captured stainless steel fasteners and unique modular design.

4. Integral pneumatic valve operates on standard plant air, will cycle most actuators in less than two seconds, and is modularized for easy clean out if fouling occurs.

5. External pneumatic valve override options are available enabling local automated valve operation. (Internal pilot momentary override is standard on all solenoids.)

6. Standard 5-way, 2-position valve operates both single- and double-acting actuators and features a standard rebreather to feed instrument air into spring side of actuator to keep out corrosives.

7. Highest explosionproof ratings suitable for use in Ex d IIC Zone I and Class I, Division 1 areas.

8. Durable enclosure and manifold/mounting plate are available in epoxy-coated anodized aluminum or 316 stainless steel. All fasteners, indicator couplers, and pneumatic valve end-caps are made of 316 stainless steel.

9. Push button set points for open and closed accurately lock in position settings which remain in place when power is removed and reapplied.

11. Rapid enclosure access with the screw-on cover saves valuable maintenance and set-up time. The cover provides a vapor tight seal and allows entry to internal components in seconds.

12. High accuracy position sensor system is solid state with no moving wear points for highly reliable and precise position feedback.

13. No bushings or shafts will wear out. Electronic module, with magnetically driven position sensor, is fully isolated from the outside environment. Actuator wear causing shaft “wobble” will not affect monitoring performance.

14. High visibility mechanical and electronic indication confirms open/closed position and solenoid status for greater safety and convenience.

15. Axiom directly attaches to VDI/VDE 3845 (Namur) actuators and many others using a compact mounting manifold system. This mounting manifold is sold separately and is designed to properly fit the Axiom to your actuator while also providing the pneumatic interface ports.

Rugged construction

Choose from the robust epoxy-coated anodized aluminum or the 316 stainless steel enclosure designed for explosionproof applications. This platform is extremely durable and is also well-suited for use in corrosive, heavy washdown and high seas environments.

Stainless steel Epoxy-coated aluminum

Sensing and communication module

The Axiom platform has all position sensing, communication or switching integrated into StoneL C-module. Users may set position switches conveniently and accurately on all modules. And easy to view instructions, along with LED indication, are boldly displayed on the module itself.

Pneumatic control

The Axiom’s pneumatic valve system consists of a low power pilot that drives the main high flow spool valve. Pilots may be selected for conventional or bus networking applications. Both stages of the pneumatic valve system have been designed for long life, high tolerance to air line contaminants, and ease of maintenance should components become fouled.

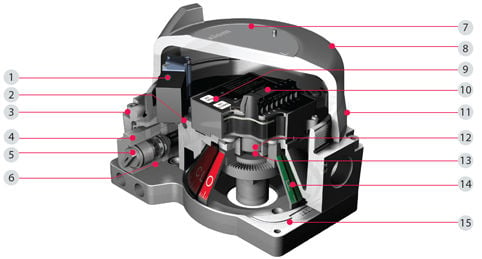

1. Universal burn out proof solenoid operates on less than 0.6 watts of power and standard version will accept 24 VDC or 120 VAC, reducing stocking requirements.

2. Prefiltered pilot valve provides additional protection from contaminants.

3. Easy removal from automated valve package is accomplished with captured stainless steel fasteners and unique modular design.

4. Integral pneumatic valve operates on standard plant air, will cycle most actuators in less than two seconds, and is modularized for easy clean out if fouling occurs.

5. External pneumatic valve override options are available enabling local automated valve operation. (Internal pilot momentary override is standard on all solenoids.)

6. Standard 5-way, 2-position valve operates both single- and double-acting actuators and features a standard rebreather to feed instrument air into spring side of actuator to keep out corrosives.

7. Highest explosionproof ratings suitable for use in Ex d IIC Zone I and Class I, Division 1 areas.

8. Durable enclosure and manifold/mounting plate are available in epoxy-coated anodized aluminum or 316 stainless steel. All fasteners, indicator couplers, and pneumatic valve end-caps are made of 316 stainless steel.

9. Push button set points for open and closed accurately lock in position settings which remain in place when power is removed and reapplied.

11. Rapid enclosure access with the screw-on cover saves valuable maintenance and set-up time. The cover provides a vapor tight seal and allows entry to internal components in seconds.

12. High accuracy position sensor system is solid state with no moving wear points for highly reliable and precise position feedback.

13. No bushings or shafts will wear out. Electronic module, with magnetically driven position sensor, is fully isolated from the outside environment. Actuator wear causing shaft “wobble” will not affect monitoring performance.

14. High visibility mechanical and electronic indication confirms open/closed position and solenoid status for greater safety and convenience.

15. Axiom directly attaches to VDI/VDE 3845 (Namur) actuators and many others using a compact mounting manifold system. This mounting manifold is sold separately and is designed to properly fit the Axiom to your actuator while also providing the pneumatic interface ports.

Rugged construction

Choose from the robust epoxy-coated anodized aluminum or the 316 stainless steel enclosure designed for explosionproof applications. This platform is extremely durable and is also well-suited for use in corrosive, heavy washdown and high seas environments.

Stainless steel Epoxy-coated aluminum

Sensing and communication module

The Axiom platform has all position sensing, communication or switching integrated into StoneL C-module. Users may set position switches conveniently and accurately on all modules. And easy to view instructions, along with LED indication, are boldly displayed on the module itself.

Pneumatic control

The Axiom’s pneumatic valve system consists of a low power pilot that drives the main high flow spool valve. Pilots may be selected for conventional or bus networking applications. Both stages of the pneumatic valve system have been designed for long life, high tolerance to air line contaminants, and ease of maintenance should components become fouled.