Reel process audits can reduce broke and defects near the spool

Reel equipment can often take a good beating from normal operation. After all, a heavy log of paper spinning at a high rate needs to transfer the sheet to a new spool, move out of the way, and be stopped in a short amount of time. At the same time, it has to maintain tight tolerances to ensure that a quality product is produced with as little waste as possible.

Periodic inspections of the reel equipment are recommended to develop a baseline with regards to its process variables (nip loads, cylinder pressures, etc.) and to its mechanical condition (alignments, looseness, tolerances, wear items, etc.). Valmet service personnel can assist you with these audits.

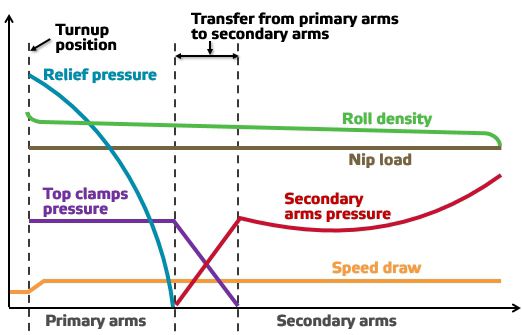

Nip load cycle during reel turnup

This illustration shows the typical nip load cycle during turnups. Using high resolution data acquisition technology, our service representatives can determine if your nip transfer cycle is working properly.

Many times, discontinuities in cylinder pressures can be correlated to offsets and defects in the paper near the bottom of the spool. Once identified, solutions can be suggested to improve the situation.

For mechanical audits, primary and secondary arm alignments are performed to determine if they are up to standards. Primary arm clamping equipment, bushings and quadrant gear tolerances also need to be checked occasionally.

If you feel your reel is in need of a process and condition test, contact your Valmet representative.