Traction for tightly wound paper rolls

Traction is the key word when winding large parent paper rolls successfully into tightly wound smaller paper rolls for customers without dishing problems and crepe marking. Slipping causes a loss of tension control required for tightly wound customer rolls, and slipping marks the paper. Traction between the paper and winder drum can be achieved by ensuring that the surface of the winder drum has the required level of roughness. However, the shell material of the winder drum is not abrasive resistant enough, and smoothening of a roughened shell surface will happen. As a solution, Valmet offers a drum roll cover with an extremely durable hard coating: Valmet Winder Drum Cover TM, with optimized surface for reliable winding.

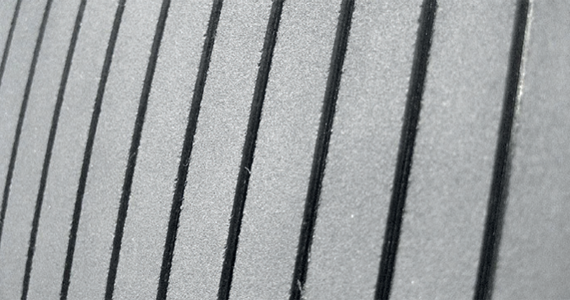

Extremely durable hard coating

Various paper grades have different levels of sensitivity to the roughness of the winder drum, so choosing the right surface roughness is important. Valmet Winder Drum Cover TM is available in a variety of roughness levels, from extra fine to coarse. After the initial wear of the sharp peaks of the sprayed-on hard coating, Valmet Winder Drum Cover TM settles down to the suitable roughness level. Over time, the roughness of the drum surface can reduce. With the durable Valmet Winder Drum Cover TM cover, this is usually not caused by wearing of the hard coating, but by the buildup of contaminants.

Valmet Service provides portable equipment for mills to gritblast the coating in order to remove contaminants and restore the surface roughness. When necessary, Valmet can also respray the hard coating onto the drum to restore the coating thickness. Both gritblasting and respraying of the hard coating can be executed on-machine – without disassembling the winder drum.

Valmet Winder Drum Cover TM is an extremely durable hard coating.

Combination of hard coating and dirt-repelling polymers

Contamination of the winder drum surface is a slow process that gradually reduces traction, weakening winder performance. To keep the winder drum in good condition longer with the desired surface roughness, Valmet offers another state-of-the-art solution: Valmet Winder Drum Cover TM-R, which is a combination of hard coating and dirt-repelling polymer. As with Valmet Winder Drum Cover TM, the hard coating provides the durable and rough surface, but now a polymer film is used to prevent contamination, allowing easier surface cleaning. This cover can also be applied and renewed on-site at the mill, for instance, every 12-18 months.

Valmet Winder Drum Cover TM-R is a combination of hard coating and dirt-repelling polymers.

Soft covers for sensitive paper grades

Valmet Winder Drum Cover WG is available for more sensitive paper grades, like coated board and paper. These grades are often vulnerable to markings from the grooved hard roll. The flexibility of the Valmet cover prevents sharp groove edges from marking the paper, at the same time allowing the soft surface of the cover to conform to the irregular CD profile of the customer roll surface. This improves the contact between paper and drum, ensuring the required traction. In addition to that, the soft, wide nip reduces the amount of air in customer rolls.

The economical rubber Valmet Winder Drum Cover WG is available in a very wide hardness range, 10-130 P&J, while the more durable 5-65 P&J polyurethane Valmet Winder Drum Cover WG-W can also be combined with Valmet iRoll.

Valmet Winder Drum Cover WG-W can be combined with Valmet iRoll.

With both the hard Valmet Winder Drum Cover TM and the soft Valmet Winder Drum Cover WG, Valmet offers you the best possible traction in the winder for tightly wound customer rolls.

Published in Valmet Roll Services catalog 04/2019

Related articles