Enduring release paper calendering: A difficult cover life

When the going gets tough, the tough get going. Calendering release paper is one of the toughest jobs a calender cover can encounter. Valmet Calender Roll Cover CL-EC has proven it is up for it.

There is currently good demand for release paper, driven by rising consumption of consumer goods and the labels and tapes they need. Valmet has delivered several OptiCalender Multinip calenders to release paper producers globally and has become the leading supplier in the field.

The properties of wood-free release paper require special papermaking conditions. It is a dense paper impregnated with a polymer, typically silicone, for release of stickers and labels and other products. It must be compressed to high density to reach low surface roughness, and it must sometimes be densified so much to be almost transparent. This must all be combined with high strength and low thickness variation for good runnability on papermaking and converting lines.

Release paper is the backing paper for holding stickers, labels and tapes.

High requirements for calender and roll covers

To achieve this demanding combination of paper properties, the release paper needs to be pressed as hard as possible with the paper as deformable as possible as many times as necessary. This means calendering in a large multi-roll calender with up to 12 to 14 roll nips, at the highest nip loads possible, with moist paper and an extremely hot nip. And to keep up with today’s fast paper machines, the calender must run at top speed.

Moreover, to keep costs in check, the roll diameter should remain moderate, although the high nip pressure resulting from the high nip load makes the cover ask for bigger rolls. These limited roll diameters mean the cover operates at the highest nip pressure it can endure at a very high cover operating temperature not seen in any other calendering process, and at a high nip frequency from the high speed and double nip.

Uneven, local loading for any reason adds to the difficult environment.

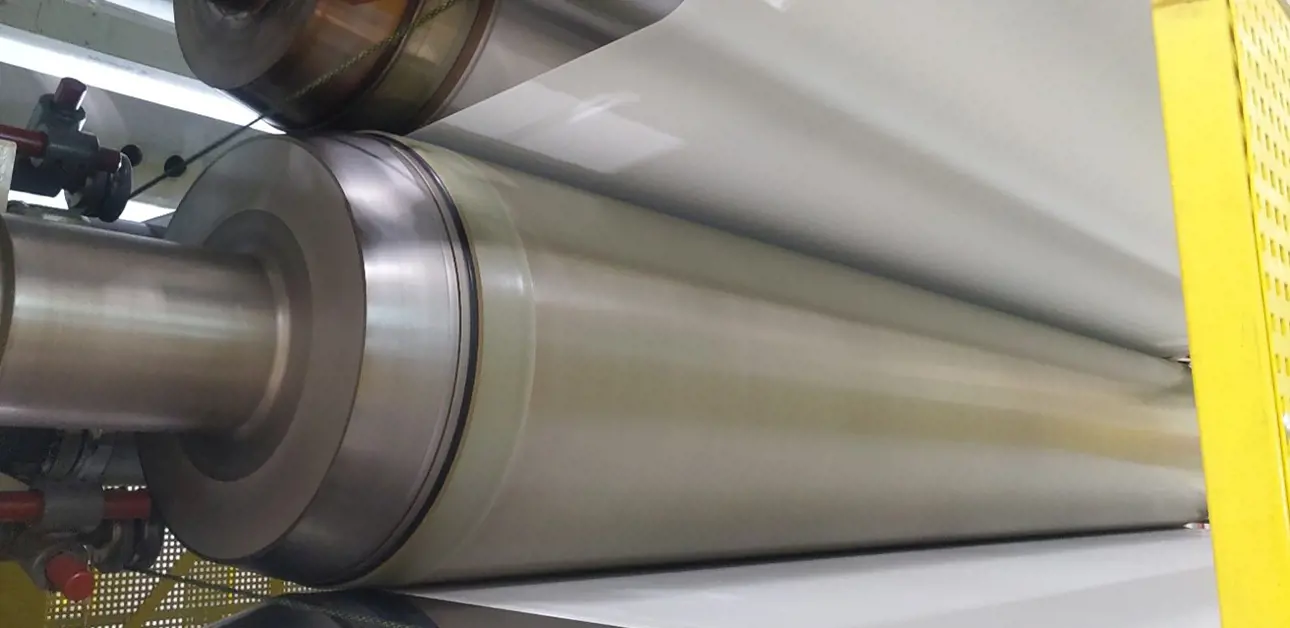

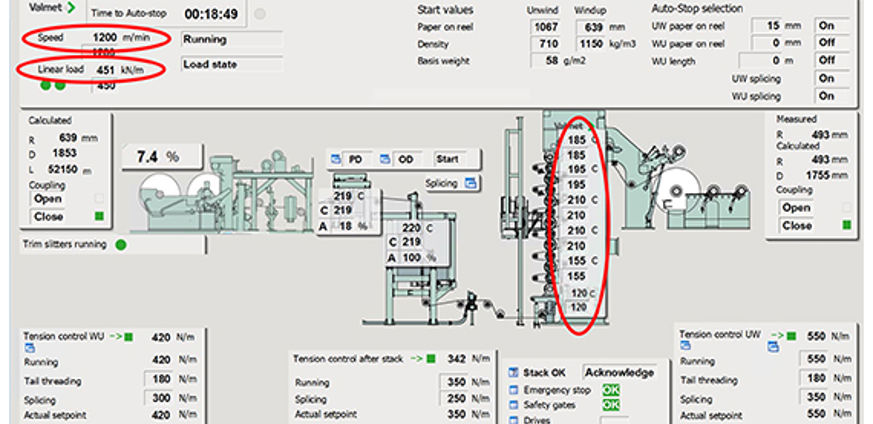

An example of a release paper calender with its extreme conditions.

In numbers this means that release paper calenders are designed up to 450 kN/m nip load, with thermo roll oil temperatures exceeding 200 °C, running at 1,200 m/min and more. This gives a nip pressure of 75 MPa at a nip frequency of 17 Hz, with a nip dwell time as short as 0.5 milliseconds.

In such conditions, it is the cover that limits the calender’s speed. Running at higher speed means we must optimize the maximum nip load to remain within the cover’s durability limits.

Tough conditions in release paper calendering inspired Valmet’s R&D to develop Valmet Calender Roll Cover CL-EC.

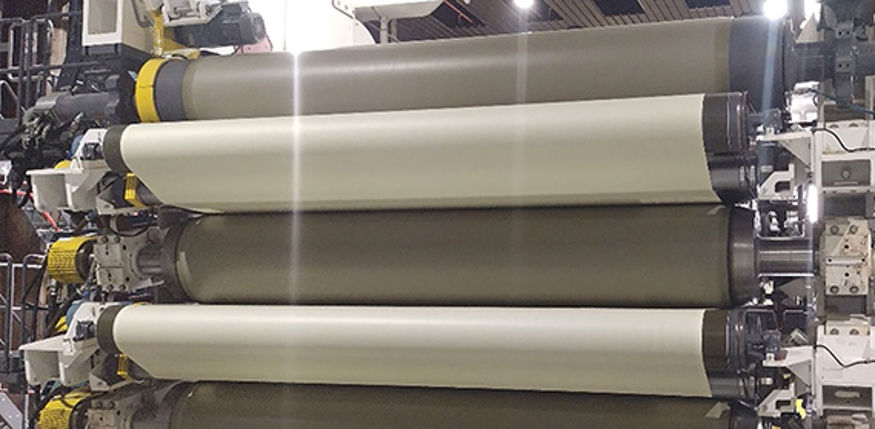

The most durable cover for extreme conditions

For durability in these conditions, Valmet initially looked at its strongest calender cover, Valmet Calender Roll Cover CL. It is strong enough to take the high nip peak stress, while its stiffness makes it ideal to exert high nip pressure on the paper to achieve the target properties.

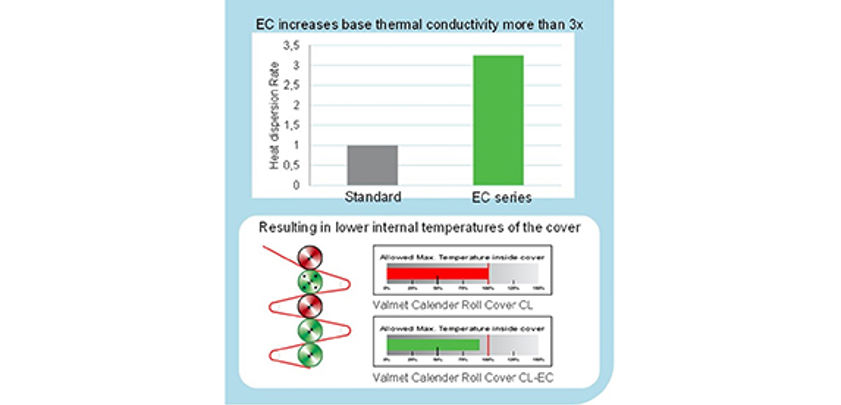

Nip simulation calculations though showed that even the durable CL cover was running at the limit of its abilities, and the drive for reduced roll diameters was pushing the cover operating conditions in an unfavorable direction. One opportunity to increase CL’s durability was to improve its ability to dissipate heat – and not only the extremely high heat given off by the thermo rolls, but also the heat generated internally from the dynamic nip loading.

This led to the development of a special version of the CL cover, Valmet Calender Roll Cover CL-EC, the most durable cover for extreme conditions.

Nip simulation calculations show the expanding durability limits of the CL-EC cover versus the standard CL cover.

High-quality release paper made profitably

Experience has shown the CL-EC cover can be run with the excessive conditions of the release paper calender. It requires a good grasp of the operating conditions, avoiding additional local loadings from contamination or web breaks.

Typically, the release paper is so strong that not many web breaks occur in the calender. Moreover, the OptiCalender Multinip calenders are equipped with web break detection from photocells, as well as with quick nip opening and web cutting, helping the roll cover protection.

Special attention is needed at the web edges, where direct contact with or close radiation from the thermo roll must also be avoided. An optimal taper design and properly set edge trimmers after the calender are a must here.

Thus, even though the high local loading and the related high internal heat generation put demands on cover durability, with good housekeeping, avoiding cover contamination, and with correct web positioning, cover damages can be prevented even with this hard life.

Valmet is the main supplier for release paper calenders, with the newest high performing OptiCalender Multinip calenders running in China, Asia-Pacific and Europe. And Valmet Calender Roll Cover CL-EC has become the cover of choice for durability in release calendering. In calenders delivered back in 2015, Valmet's covers are still the covers of choice. After more than seven years of operation, it is still making high-quality release paper profitably.

With such proven performance CL-EC offers reliable performance in any soft calender, supercalender, or multi-nip calender with any paper grade - targeting expecially the toughest calendering jobs out there.

Today, CL-EC is the standard cover for Valmet’s release paper calender. It runs reliably in all the release paper calenders Valmet has delivered in recent years.

Related articles