Finding the sweet spot for the polymer dose

The Mitchells Plain Wastewater Treatment Works installed two Valmet Total Solids Measurements (Valmet TS) in its sludge cake pipelines to provide inline feedback on the dry solids percentage of the sludge cake. The data revealed an interesting finding for optimal polymer dosing.

Sludge handling and dewatering contributes a large percentage to the operating cost at a municipal wastewater treatment works, specifically through the use of flocculation aids such as polyelectrolytes. During a recent extension and upgrade to its sludge dewatering facilities, the Mitchells Plain Wastewater Treatment Works operated by the City of Cape Town, South Africa, took the opportunity to conduct a long-term pilot trial of emerging technologies in municipal wastewater treatment. The plant currently treats approximately 400,000 population-equivalents of predominantly municipal wastewater.

From visual to quantitative evaluation

The cost of purchasing polymer is up to 10 percent of the total process-driven cost, and between 15 and 25 percent of the sludge dewatering costs. While other process parameters can be optimized by measurement (such as the measured Dissolved Oxygen or Ammonia concentrations used for aeration), the traditional sludge dewatering control had been for the most part left to visual evaluation and the experience of the operator on duty, with intermittent sampling and laboratory analysis. The installation of two Valmet TS measurements directly measuring the water content of the sludge cake offered the opportunity to augment the qualitative experience and visuals with quantitative numbers.

Trial for polymer dosing

Mechanical sludge dewatering at Mitchells Plain is achieved with belt filter presses. The dewatered sludge cake is conveyed to open-hopper progressing cavity pumps, which in turn pump the cake into elevated hoppers for removal by truck. Two Valmet TS units were installed in June 2017, one in the Primary Sludge pipeline and the second in the Waste Sludge pipeline.

The main operating parameters for effective belt press operation are solids loading (in kg per hour) and polymer dosing (kg of polymer per tonne of solids). Valmet now also supplies the operator with cake dryness, which can be used to observe and develop trends showing relationships between the polymer dose and the cake solids content.

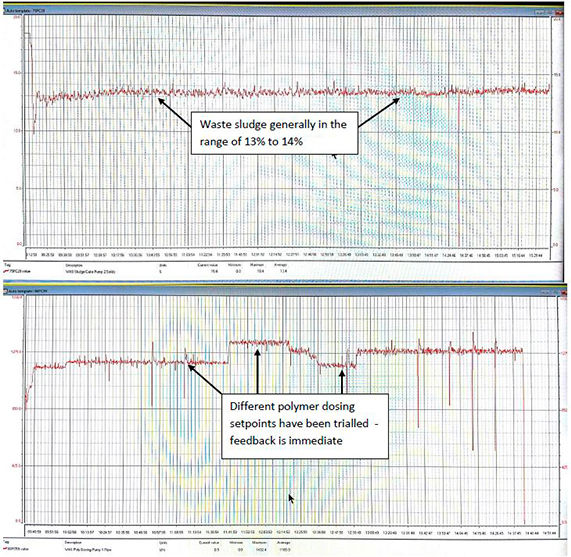

Based on a trial of different polymer dosing rates throughout a shift (see graphs below), the operator maintained a reasonably consistent sludge cake output of between 13 and 14 percent dry solids.

The optimal polymer dosing rate represents a polymer saving of approximately 20 percent.

“Sweet spot” for polymer dose

For primary sludges, the relationship between the polymer dose and the sludge cake output has been reasonably consistent, with a clear “sweet-spot” between 2.2 and 2.5 kg Poly per dry tonne of solids. This relationship has confirmed the experience observed at other City of Cape Town facilities. However, waste sludge has yielded an interesting result. Two sweet-spots have been observed, notably at approximately 3.5 kg/dry tonne and 5.5 kg/dry tonne, with sludge cake achieving results of 14 percent solids consistently at the desired loading of 200 kg/hr/meter of belt width. The dewatering performance is less successful in the range of 4.0 to 5.0 kg/dry tonne.

The overwhelming conclusion is therefore that – with other parameters being equal – the City of Cape Town operators should strive to operate at the lower dosing rate of 3.5 kg/dry tonne. Bearing in mind that the earlier operational costs were initially calculated on the basis of 5 kg/dry tonne of solids, equivalent dewatering results can now be achieved using between R200,000 to R400,000 less polymer per annum. This represents a polymer saving of approximately 20 percent. The sludge cake solids content information supplied by Valmet TS has also enabled operators to more rapidly become accustomed to the sensitivities of dewatering process control.

Sludge-cake solids content (top) and the polymer dosing (bottom) where the operator has trialed several different polymer dosing rates through the course of the shift

Valmet Total Solids Measurement (Valmet TS), based on microwave technology, is a reliable and accurate meter for all wastewater sludge treatment applications (0 – 40% total solids), providing savings in energy, polymer dosing, and transportation.

This article is based on a presentation given by Zaheer Ortell, Wastewater Branch, City of Cape Town, at the Water Institute of Southern Africa (WISA) conference and exhibition 2018.

TEXT Veska Spassov, Kevin Samson, Zaheer and Ortell

Article published in Forward magazine 2/2019.

Related articles