Ease of assembly and use, lower construction costs, and improve safety

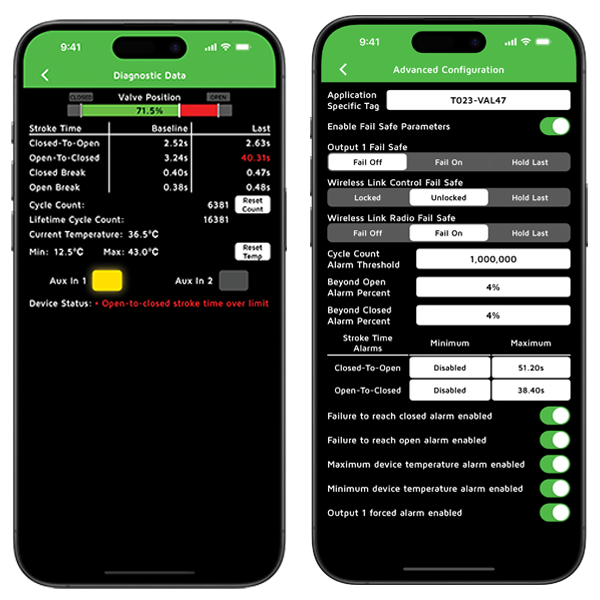

Lower your construction costs and shorten installation time by interconnecting your automated valves using a Stonel platform and a protocol system. And now when you add the Stonel Wireless Link, you don’t have to remove the cover for trouble-shooting or diagnostics. You can stroke your valve, read the device tag and diagnostics, and set the valve to open or closed… ALL from a safe, convenient location.

Compact size

Stonel products are feature-rich and designed to meet the increasing need for smaller, lighter and more durable products to conform to the needs of moveable process skids and flexible manufacturing. The integral solenoid allows for smaller overall envelope size because there is less tubing and cable. And the input/output (I/O) points reside within the valve control terminal (VCT) so minimal I/O racks are utilized.

Precise monitoring

Stonel Axiom and Prism platforms use solid state continuous sensors with increased reliability and precise position measurement, compared to mechanical or proximity-reed technology. These sensors enable more sophisticated valve diagnostics, leading to reduced maintenance costs over the valve’s life cycle.

Predictive maintenance

Avoid downtime or danger due to valve failure by having easy access to information about critical parameters. Using Wireless Link you can remotely monitor valve function, including sensor temperature and cycle counts. With access to cycle count data, you can perform valve maintenance when it is truly needed and replace parts prior to wearing out.

Improved safety with Stonel Wireless Link

Safely, securely and conveniently access difficult to reach communication and control modules. Using standard iPads or iPhones with the Stonel app, further cost savings may be realized. Security is assured with operational/lockout privileges.