iRoll - intelligent roll solutions for board and paper making

The fastest on-line profile measurement tool

Valmet iRoll technology improves production efficiency and product quality by assuring optimal runnability of board and paper machines. Papermaker can obtain significant cost savings by improved nip profiles, parent roll hardness profiles and tension profiles as well as printer and converter satisfaction.

Profile variation reduced by 40%

80% less winding broke

50% reduction in sheet breaks

iRoll technology for controlling paper and nips

iRoll may be utilized on a covered roll in board and paper machines to expand the roll’s primary function to include use as a transducer for sensing cross-machine nip linear load or sheet properties such as tension and parent roll hardness profile.

iRoll can be connected to automation and data collection systems. It also has advanced tools for data analysis, drawing color maps and more. With up to 200 data points in the cross-machine direction, iRoll provides high resolution profile feedback. Data from iRoll is truly online as it is updated up to 10 profiles per second.

How does the iRoll work?

- Measures and controls paper and board properties, not only nip properties

- Removes skewness and other errors in nip load profiles

- Improves sheet tension profiles and runnability of end product

- Determines correct crowning for roll covers and exact timing for roll changes

- Monitors condition and tuning of nip loading equipment

- Online control of web tension and roll hardness profiles, replacing unreliable thickness profile scanners

- Provides full-speed online profile measurement with high CD-resolution

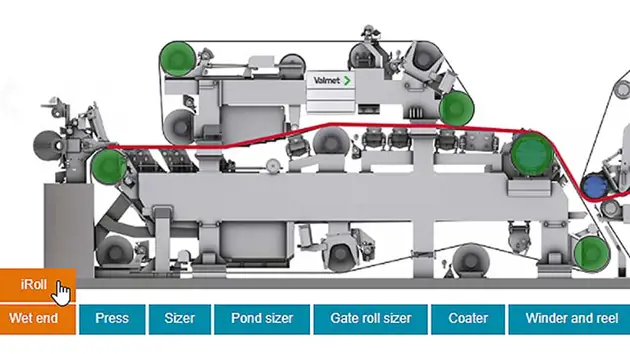

Explore our intelligent roll solutions from interactive demo

By exploring the roll application demo you will learn more about the optimal iRoll positions in your production line.

Start exploringRead more detailed product information from Solution Finder

iRoll Press enables online nip profile measurement in press nips to assure optimal dewatering in the nip.

iRoll Sizer shows size press nip load and applicator rod profile online and enables coat weight profile improvement.

iRoll Tension profile measurement reveals the sheet runnability characteristics online and it can also be used on felts and wires.

iRoll Temperature online measurement for rolls and optimizing drying process

iRoll Reel provides parent roll hardness profile and online control.

iRoll Coater for better blade profiles and coating quality.

iRoll Winder monitors the end product quality and reveals winding issues such as discontinuities in the nip loading.

Implementations of iRoll

The iRoll intelligent roll system can be installed as a permanent nip load profile measurement tool, as permanent tension profile measurement tool, roll hardness profile measurement tool or as iRoll portable service. For permanent iRoll applications, it must be used in conjunction with a roll cover.

From timely to condition based-monitoring

Monitoring based on iRoll nip profiles, vibrations and optimization data are some examples where roll condition information is analyzed. This provides security for our customers that technical solutions and recommended upgrades are based on their actual needs and goals.

Intelligent Roll - remote support service

Valmet's remote support and analysis services connect papermakers to Valmet experts online, if they are using iRoll, roll condition monitoring or other Intelligent Roll Solutions. View case examples here >>

iRoll portable for temporary troubleshooting and process analysis purposes

iRoll portable technology can be used for:

- Improving tension profile and solving runnability issues

- Improving paper quality and profile related troubleshooting

- Measuring nip profiles for determining proper crowns

- Tuning up winding/reeling recipes

- Condition tests

- Improving parent and customer roll hardness profiles

- Press nips, sizers, reels, winders, coaters, fabric tension profiles

Questions?

Do not hesitate to ask our experts about intelligent roll solutions. They will help you.

Fill the form hereWith iRoll, we have made a huge step forward in improving the winding quality.”

References and articles

Related pages

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}