Sizer consumables and related accessories for board and paper machines

Operational excellence for film sizing and coating

Ensure your operational excellence for film sizing and coating of paper and board with our sizer consumables and carefully selected accessories, like sealing blades and rod shafts.

Customer case: Valmet sealing blade bent minimizes unplanned shutdowns

A WFU machine running in Europe was using conventional sealing blades. Their lifetime was a maximum of 12 days, which meant frequent shutdowns for worn blade changes.

The blades were replaced by Valmet’s new pre-bent sealing blades. Their lifetime is a minimum of 21 days, which is the machine’s shut-down interval. Changing the blade can therefore be carried out during pre-planned shut-downs and no unplanned shutdowns are experienced due to worn blades.

Results:

The lifetime of the pre-bent sealing blade is minimum a of 21 days, which is the machine’s shutdown interval.

Changing the blade can be carried out during the pre-planned shutdowns.

Sealing blades - excellent wear and corrosion resistance secure long lifetime

Our blades have different geometries for every process: surface sizing, surface sizing and coating, and high solids pigment coating. The design may also be optimized for your machine’s needs, to eliminate uncontrolled sealing blade bending, coat weight increases and unexplained splashing and misting.

In our newest product, Valmet Sealing Blade Bent, we have combined the excellent qualities of our traditional sealing blades with a pre-bent design. The design decreases the angle between the blade tip and the roll surface. It also increases the contact area in which the sealing blade touches the roll surface, reducing the surface pressure between the tip area of the sealing blade and the surface of the roll.

We offer fast and flexible deliveries – our sealing blades are packaged in cardboard boxes to prevent damages during transportation and for easy storage.

Rod shafts are available for old and new machines

Valmet’s rod shafts are designed to be fastened without tools ensuring quick replacement and reliable fastening. We always have rod shafts in stock in our local warehouses ensuring fast and reliable deliveries.

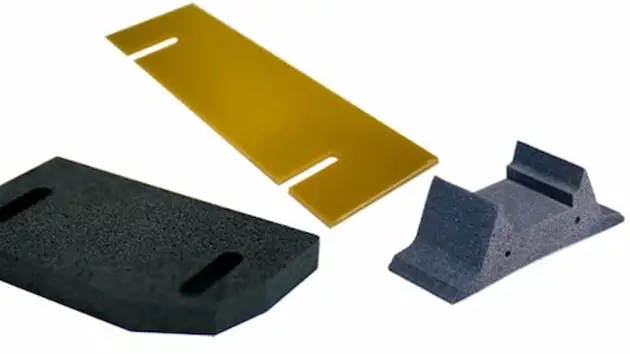

Accessories for every need

Our selection of other sizer accessories includes end seals, edge wipers, loading hoses, edge shower protecting plates, sampling tools and installation aids.

Explore related services

Our optisizer sizing solutions