Maximum drying efficiency with minimum energy consumption

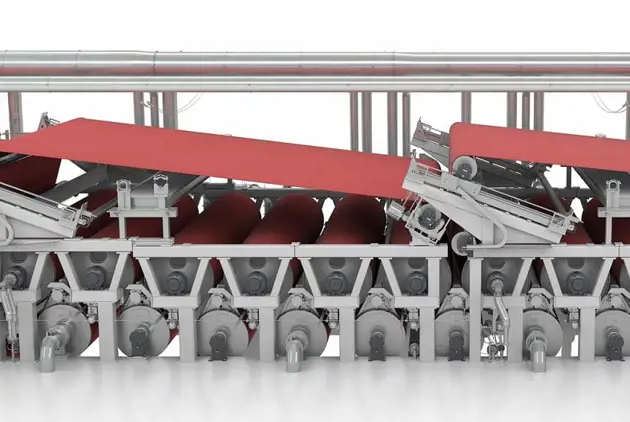

Valmet cylinder drying for board and paper machines

In papermaking, it is vital to ensure maximum drying efficiency with minimum energy consumption. Valmet cylinder drying portfolio is able to provide perfect solutions for all customer needs regardless of your grade, machine speed, or basis weight. Our offering also includes rebuilds, components, and services, in addition to various drying analyses and optimization services.

Discover Valmet's cylinder drying selection

Get to know our cylinder drying product family OptiRun dryer section and Runnability Systems. Click on the link below to read and find out more on our drying solutions.

Proven technology for all needs

Valmet cylinder drying family features optimized steam consumption with effective ventilation and heat recovery for energy-efficient operation. As the efficiency of the entire machine is affected by the runnability of the dryer section, open draws are minimized and the wet web is well supported at the beginning of the dryer section. This ensures trouble-free web transport and production, regardless of machine speed or grade.

Controlled web shrinkage and stretch optimize end-product quality. Optimized geometry of single-fabric and double-fabric sections target even moisture profiles and flatness with minimum energy input.

Want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts

Do you want to know more about Valmet's compact concept?

OptiRun compact concept is a game-changer in paper machine dryer sections. Ensuring good runnability, improved drying efficiency and excellent tail threading, this is the biggest change in drying section design in the last 35 years.

Read the articleCustomer story: Superb dryer section for APP Jingui BM2

APP Jingui BM2 is a coated cardboard production line, with a web width of 8,850 meters and a design daily capacity of nearly 4,200 tonnes. According to APP, Valmet’s integrated design in the drying section has allowed overall energy savings. This includes the compact and optimized dryer cylinder and guide roll arrangement, with Valmet Runnability Systems, OptiAir Hood and other systems, which have all worked well together. Watch the video to learn more.

Learn more about the services for dryer section

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookExplore our latest board and paper press releases

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China