Press felts for tissue machines

Reliable performance throughout the felt lifetime

Valmet's tissue felts are designed to ensure safe operations, reliable machine performance and low energy consumption. Our strength is the long and thorough expertise of not only paper machine clothing, but also production and process technology and maintenance of tissue machines.

Fast start-up

Even run

Good CMD stability

High dewatering

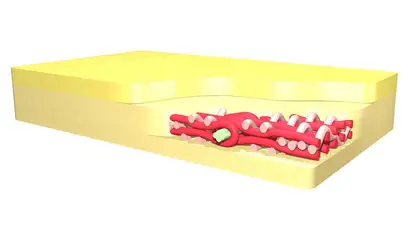

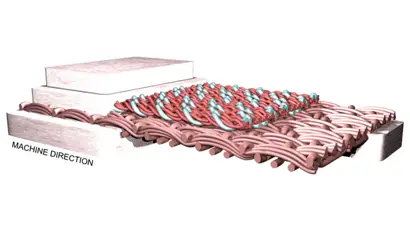

Valmet Press Felt STM and Valmet Press Felt SMO

The STM and SMO felts are especially designed for tissue machines. The felt designs respond to the requirements tissue makers have in respect to machine performance, tissue quality, energy savings and cost reductions.

The felts feature

- Fast felt start-up

- Unchanged felt properties during the lifetime

- Good felt CMD stability

- Even run: no vibration, marking or breaks

- No hairiness and easy cleaning

Felt dewatering

The dewatering of the felts is high. The smooth and dense felt surface gives high hydraulic pressure which contributes to good nip dewatering. The open back side, in turn, affects the suction roll vacuum.

Tissue quality

Valmet Press Felt STM and SMO contribute to good tissue quality. The paper properties are very even as both the CMD and MD profiles are even. There is no marking, no weak points. Also, with these felts no holes in the paper occur thanks to:

- smooth and tight felt surface and resin impregnation (SMO), no hairy surface in the beginning

- a structure that is easy to keep clean; no stickies, uneven plugging etc. in late life

Energy consumption and cost savings

The total energy consumption of the felts is low. High dewatering leads to high dry content, low steam pressure and low hood temperature. Also the fact that the felt properties remain unchanged during the felt lifetime contributes to a good energy consumption level.

Cost savings are achieve with the felts through

- high dry content as a result of good nip dewatering

- fast start-up at maximum running speed

- long running time thanks to unchanged felt properties and less felt wearing

- seamed felt’s safer, fast and easy installation: shorter installation time and less manpower needed for felt change

Need support with your tissue machine press felts?

Our experts are here for you. Send us your question and we'll come back to you by return.

Contact usArticles and news